You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trigger job or aftermarket?

- Thread starter joe sixgun

- Start date

stagpanther

New member

^^^^^Don't know what you're asking for it--but I've installed and used a couple of these--great all-around performer with good safety margins built-in and at under $80 or so a great drop-in solution to a stock "gritty mil-spec 6.5 lb'r" disease. : )

Do not do that!

[quote:] Illusion you nailed it. I recently read an article in a magazine that clearly illustrated this condition. What harm would be done by relieving some of the angle from the notch on the hammer?

No offense Joe, but you have shown that you DO NOT know what you are doing.

Rounding (or relieving) an angle is begging for disaster. As stated previously the hardening on the hammer/trigger sears is thin and this is 'why' ONLY polishing is marginally allowed. Think 1000-1200 grit (or less) on an absolutely flat (as in glass pane backed) "scary-sharp abrasive" sheets and an absolutely square edge. NEVER change angles OR round any sear edge. Maintaining the identical angles 'as-was' is how the stock trigger is improved. Some will advocate reduced power springs but they are NOT necessary IF done properly. Most people DO NOT have the patience or ability to maintain the original angles long enough to get a glass-like polish surface. A moly grease like Chip McCormicks 'Trigger Slick' will assist in a (nearly) creep-free break.

BUT again, keep in mind that the 'jack-back' is always going to remain on a stock trigger. MY ADVICE: Bite the bullet. Cough up the $85 for the RRA Two-stage trigger while it is still on sale and chuck the original into the scrap parts bin. The RRA referred to previously has a light second stage with a crisp break and a quick lock time.

Trust me on this.. You will never look back!

[quote:] Illusion you nailed it. I recently read an article in a magazine that clearly illustrated this condition. What harm would be done by relieving some of the angle from the notch on the hammer?

No offense Joe, but you have shown that you DO NOT know what you are doing.

Rounding (or relieving) an angle is begging for disaster. As stated previously the hardening on the hammer/trigger sears is thin and this is 'why' ONLY polishing is marginally allowed. Think 1000-1200 grit (or less) on an absolutely flat (as in glass pane backed) "scary-sharp abrasive" sheets and an absolutely square edge. NEVER change angles OR round any sear edge. Maintaining the identical angles 'as-was' is how the stock trigger is improved. Some will advocate reduced power springs but they are NOT necessary IF done properly. Most people DO NOT have the patience or ability to maintain the original angles long enough to get a glass-like polish surface. A moly grease like Chip McCormicks 'Trigger Slick' will assist in a (nearly) creep-free break.

BUT again, keep in mind that the 'jack-back' is always going to remain on a stock trigger. MY ADVICE: Bite the bullet. Cough up the $85 for the RRA Two-stage trigger while it is still on sale and chuck the original into the scrap parts bin. The RRA referred to previously has a light second stage with a crisp break and a quick lock time.

Trust me on this.. You will never look back!

For 85 bucks it's not a bad deal to get the RRA NM trigger. Even if it does go softer after a few thousand rounds that isn't a big deal unless you are trying to make trigger pull weight at equipment check in for a leg match.

If you just want a lighter trigger, grease and a JPE spring kit will do that. But there is a reason why the bulk of people responding to this thread have recommended a replacement trigger. I spent the money on SSA and G2S triggers whenever I could get them on sale, but I was building Service Rifles which really need a good trigger to help the shooter be competitive.

Jimro

If you just want a lighter trigger, grease and a JPE spring kit will do that. But there is a reason why the bulk of people responding to this thread have recommended a replacement trigger. I spent the money on SSA and G2S triggers whenever I could get them on sale, but I was building Service Rifles which really need a good trigger to help the shooter be competitive.

Jimro

There's no start filling and grinding on any trigger when doing a trigger job. Polish only. And change springs.

Like illusion says, changing angles is "begging for disaster". You can make a nice safe target rifle into an uncontrollable FA. Or have the trigger not work at all.

"...dry firing the crap out of it to try to work put some of the gritty feeling..." Dry firing doesn't do that. Dry firing is a well known and respected training technique, but it ain't going to fix a bad trigger.

Like illusion says, changing angles is "begging for disaster". You can make a nice safe target rifle into an uncontrollable FA. Or have the trigger not work at all.

"...dry firing the crap out of it to try to work put some of the gritty feeling..." Dry firing doesn't do that. Dry firing is a well known and respected training technique, but it ain't going to fix a bad trigger.

dakota.potts

New member

As has been said, if you decide you must work on it yourself, do not use files, dremel, or sandpaper. Some say 1200 or higher sandpaper is higher, but I would not use anything but a very fine stone. You must not change any geometry or dimension which is why you're only polishing. You cannot remove or reshape anything, only smooth out the high or rough parts to improve your surface finish and reduce contact friction. Anything else can become unsafe very fast. As stated, there is also the issue of hardening.

I would just spend $60-80 on the ALG and be done with it. You're not ready to work on your trigger yet side you don't have an understanding of how it works. Asking questions is the first step to understanding but it's not a job I think you should try yet.

Just my opinion. I've been wrong before

I would just spend $60-80 on the ALG and be done with it. You're not ready to work on your trigger yet side you don't have an understanding of how it works. Asking questions is the first step to understanding but it's not a job I think you should try yet.

Just my opinion. I've been wrong before

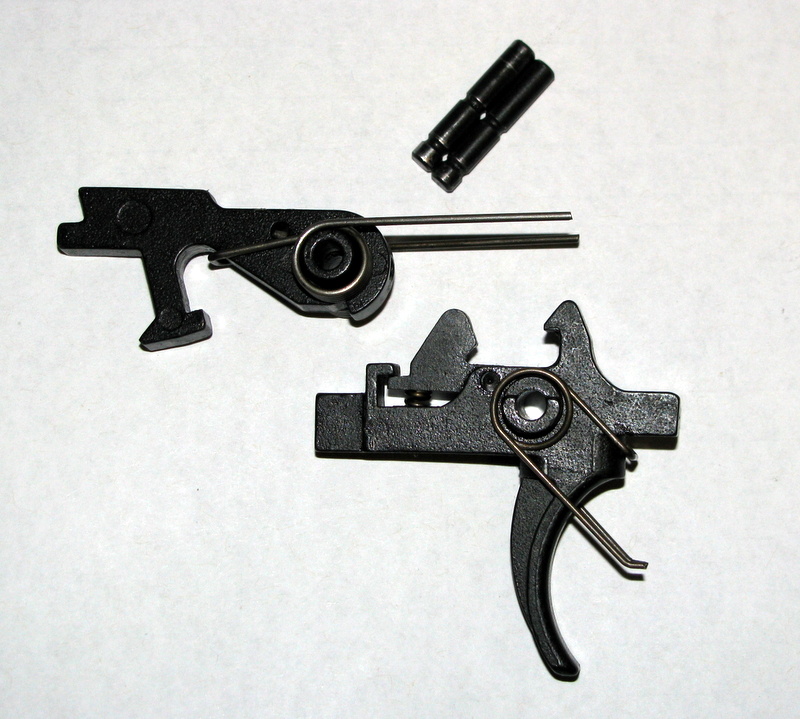

For the benefit of the OP, that is a never used RRA National Match 2-stage trigger in my previous post.

I've had it in my parts bin for at least six...maybe closer to seven years. It was intended to be paired up with a varmint rifle upper that I built but wound up selling the upper before I completed the lower.

I am asking $75 shipped.

I've had it in my parts bin for at least six...maybe closer to seven years. It was intended to be paired up with a varmint rifle upper that I built but wound up selling the upper before I completed the lower.

I am asking $75 shipped.

Polish the hammer surface and sear surface using a Dremel tool on the LOWEST speed, using one of the cotton disks and some Jewelers rouge. Both surfaces will shine like chrome. That's it. Don't keep grinding. That's it. I have ceramic stones and use them regularly, they are a great tool. But the Dremel will work just fine, JUST DON'T GET CARRIED AWAY. Polish, that's it. Know when to say when. The trigger pull will be smoother and somewhat reduced. I can't imagine you want a "Match" trigger with a 2LB pull on an AR. Good Luck. I hope that helps.

Last edited:

joe sixgun

New member

That is where I am going to start. Then maybe some springs. Apparently any more than that I just might throw the earth off its axis or plunge the world into eternal darkness or something...lol. Thanks for all the advice folks. It has been helpful. I promise to be careful. No grinders or plasma cutters.

dakota.potts

New member

I know it seems some people are being overly cautious (and maybe they are) but it's surprisingly easy to create an unsafe condition with slam fires or discharges without a trigger pull. It's possible to change dimension or geometry without knowing it, especially if you're inexperienced in metal working. That's the only reason for the caution. It's also why, for me, $50-70 on an improved trigger might be worth it over the possible risk.

joe sixgun

New member

Yes, I get it. Safety is #1. I don't want an unsafe weapon either. All advice in this thread is taken seriously. Thank you all.

gunfighter48

New member

I like single stage triggers. I have a Timney 4lb trigger in my M&P 15 Sport 5.56 and a 4.5lb in my DPMS Oracle LR308. Pricey yep and worth every penny!!!!!