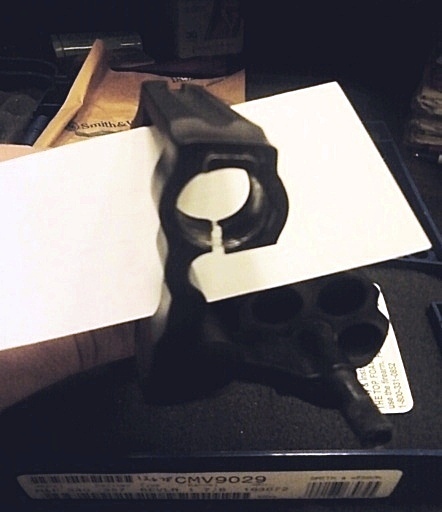

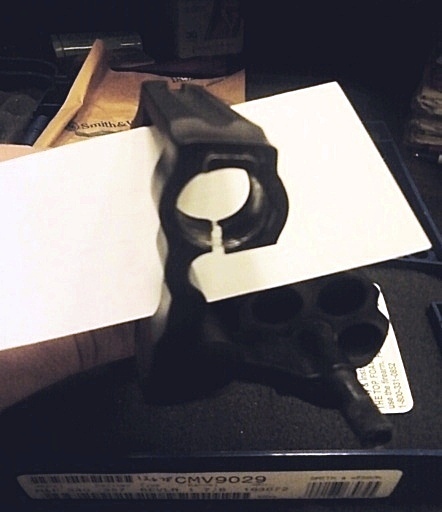

This is an M&P 340, Scandium-frame .357 J-Frame. The owner fired six rounds of .38 Special through it without issue. The first shot of .357 blew up the gun. The operator was unharmed, as all of the unpleasantness happened forward of the muzzle.

The .357 loads were factory ammunition, and quite mild. It wasn't an ammunition issue.

It appears that the barrel torqued fairly hard. The frame cracked beneath the forcing cone, allowing the barrel to come unscrewed by about 3/8". The barrel shroud sheared off. The actual barrel easily unscrewed the rest of the way.

So, I have to ask, is Scandium really feasible for this load, on this frame? This is the second failure of this material I've seen, and there are several other documented cases. As you can see in the third picture, the barrel (which is very light and thin steel) screws directly into threads carved into the Scandium.

Would a pinned-in steel bushing on the frame help, perhaps?

This is not a thread about how some people don't like S&W for whatever reason, so please don't take it there.

The .357 loads were factory ammunition, and quite mild. It wasn't an ammunition issue.

It appears that the barrel torqued fairly hard. The frame cracked beneath the forcing cone, allowing the barrel to come unscrewed by about 3/8". The barrel shroud sheared off. The actual barrel easily unscrewed the rest of the way.

So, I have to ask, is Scandium really feasible for this load, on this frame? This is the second failure of this material I've seen, and there are several other documented cases. As you can see in the third picture, the barrel (which is very light and thin steel) screws directly into threads carved into the Scandium.

Would a pinned-in steel bushing on the frame help, perhaps?

This is not a thread about how some people don't like S&W for whatever reason, so please don't take it there.