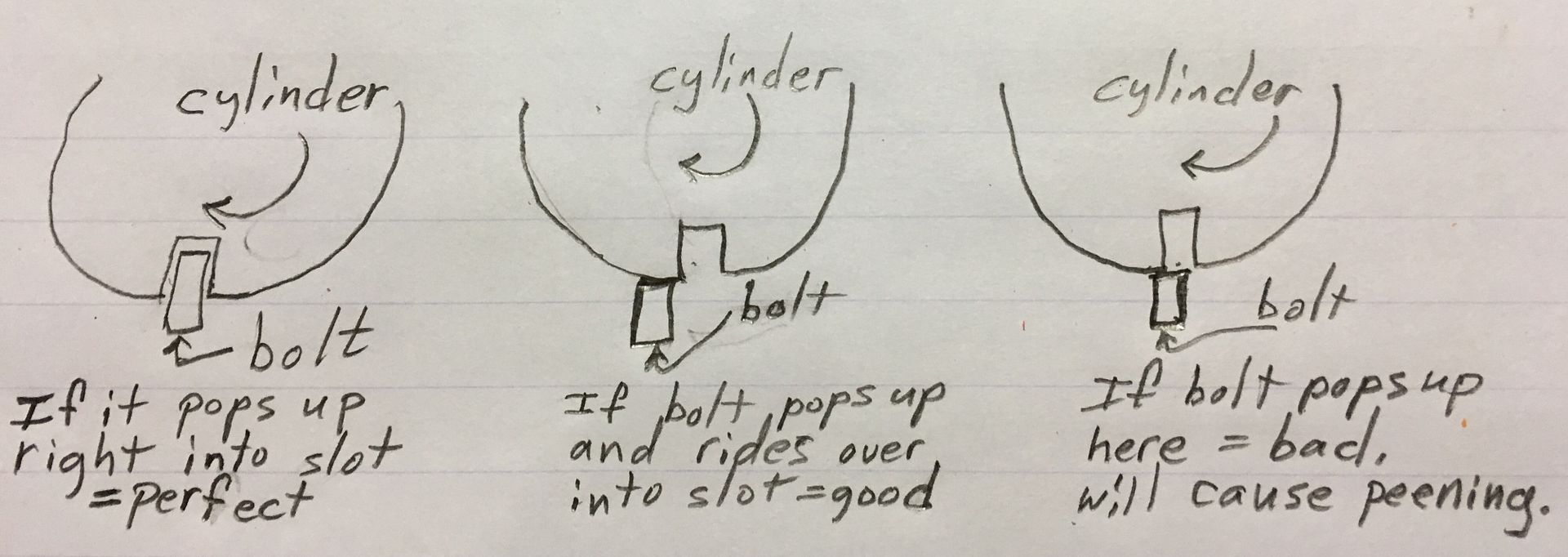

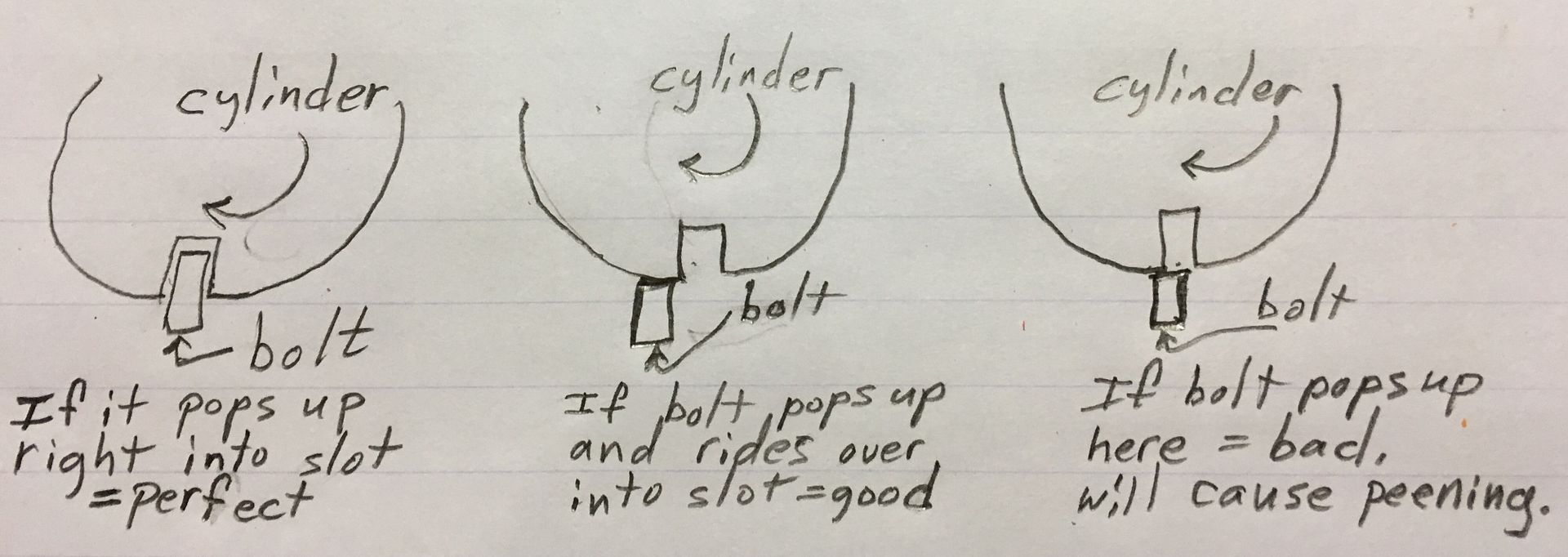

When the bolt pops up, there are only two acceptable choices. (all done with the cylinder installed on the gun) One being that the bolt pops up and the cylinder locks immediately and the bolt directly hits the slot and is perfect. This is rare and also will not be the case after the cam and bolt leg wears any at all. The other preference is that when the bolt pops up, the distance that the cylinder will still turn before lock up would equal the width of the bolt, which will mean the entire bolt surface engaged the cylinder and then slid into the slot. It's only bad if the bolt pops up and then the cylinder still has only a hair more to turn before lockup. That means the bolt is only contacting the cylinder right at the edge of the slot. I'll draw a picture and add it to this. I know it isn't easy to see, from my description.

You aren't going to do much damage by watching it slowly. It isn't going to peen the slots after only one or two or even ten hits. It's after a dozen or more times that you'd start to see it. And hopefully it's not even an issue.

You can't really "see" the bolt touching the cylinder, but you can see when it pops up and how far the cylinder will turn after that before lockup.

Okay.... here's a cutaway pic of the cylinder to show what I was so long-winded in describing.

You aren't going to do much damage by watching it slowly. It isn't going to peen the slots after only one or two or even ten hits. It's after a dozen or more times that you'd start to see it. And hopefully it's not even an issue.

You can't really "see" the bolt touching the cylinder, but you can see when it pops up and how far the cylinder will turn after that before lockup.

Okay.... here's a cutaway pic of the cylinder to show what I was so long-winded in describing.

Last edited: