When I think of defining quality in terms of manufacturing I think of Deming.

In the 1970s, Dr. Deming's philosophy was summarized by some of his Japanese proponents with the following 'a'-versus-'b' comparison:

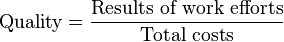

(a) When people and organizations focus primarily on quality, defined by the following ratio, quality tends to increase and costs fall over time.

(b) However, when people and organizations focus primarily on costs, costs tend to rise and quality declines over time.

This is a simple ratio which is telling.

When it comes to evaluating quality I think of a company or product in terms of Deming 7 deadly sins. For me the ones that apply to guns and gun manufcturing companies are in bold. I often ask myself how many of these "sins" is a particular company committing.

Lack of constancy of purpose

Emphasis on short-term profits

Evaluation by performance, merit rating, or annual review of performance

Mobility of management

Excessive medical costs

Running a company on visible figures alone

Excessive costs of warranty, fueled by lawyers who work for contingency fees

Then one can consider his “Lesser Category of Obstacles”:

Neglecting long-range planning

Relying on technology to solve problems

Seeking examples to follow rather than developing solutions

Excuses, such as “Our problems are different”

Unless you work at these companies you cannot know the exact processes using in manufacturing or the exact motivations but that does not mean we cannot make evaluations.

I try to determine how many of these "sins" the company is committing. This can give you an outside snap shot of the "Quality" of a company. For me this is better than picking up one example and declaring something. Looking at multiple examples over time and applying this type of system is the only way for a consumer to measure quality.

Applying these to pistols like the 1911 is not an easy task and there is not necessarily a universal correct answer but IMHO if you are not thinking in these types of terms you are not really considering "quality" you are considering "perception." This applies directly to the MIM debate IMHO.