Model12Win

Moderator

The nitraterationating will help burn that stubborn paper. Also don't use too thick a paper. One that holds up in your cartridge box out on the trail, but not so thick as it won't burn well.

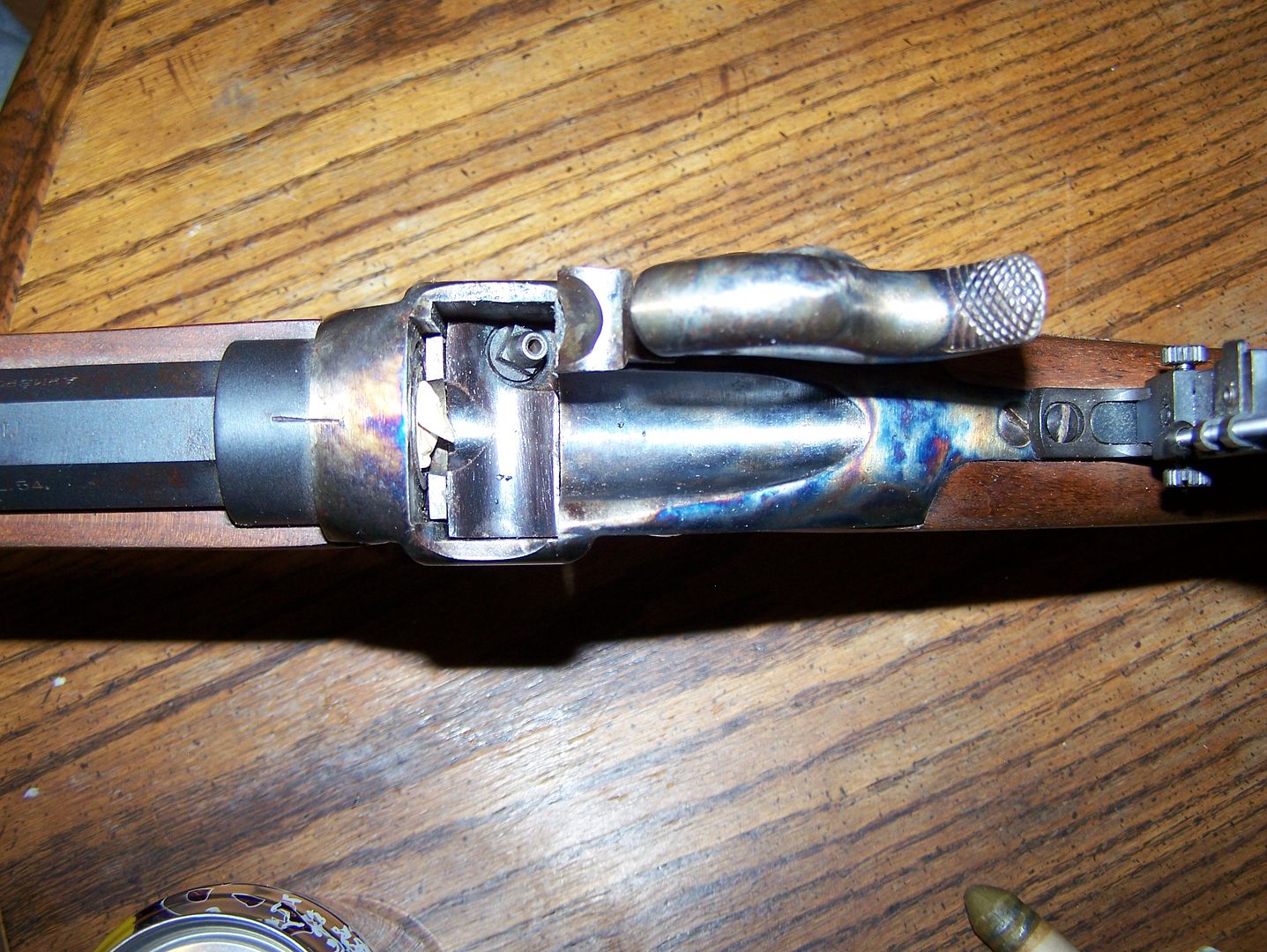

You lose a few particles of powder but it doesn't affect anything and I have yet to get any under the forearm or inside the action. I fail to see how it could get under the forearm anyway unless you just blew it in that direction maybe. I can see maybe getting between the breech block and receiver but that would burn off when fired and you would never notice it.

What glue do you use? I was told waterglass.

Sounds like they lost a lot more powder than I do. I never had any of that misfire because of the end folding over. Maybe if the cutter gets dull it will do that, I dunno.

I use a mixed solution of 2{?} parts rubbing alcohol, one part hydrogen peroxide, and one part Murphys Oil Soap in a spray bottle; so I can clean the action when it gets stiff.

If you can get a better type of paper clue in a office business store, you might be able to use hair curler paper for the whole cartridge case. Smooth steel tapered dowels are the best.

You do want to make sure, that you have only 1 sleeve of hair curler paper covering the base of the charge.