Either round will chamber and fire interchangeably, the biggest difference is a more generous throat in 5.56 chambers. This aids reliability in military rifles.

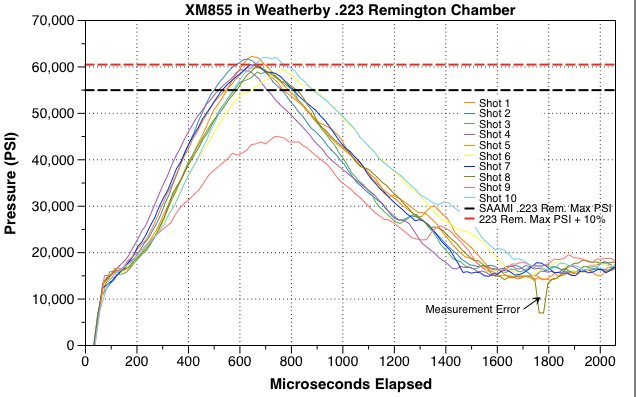

5.56 CAN be loaded to SLIGHTLY higher pressure than 223. But I seriously doubt that any commercially loaded ammo is going to be loaded right to the max. It is highly doubtful that you'll ever find 5.56 ammo that actually exceeds 223 pressure limits. If you handload and like to push the envelope maybe.

If your rifle has a 5.56 chamber either cartridge works fine. There is the potential of being overpressure if 5.56 is loaded in a 223 chamber. A bolt rifle is strong enough to easily handle this.

In the real world the only concern is that 5.56 fired in a semi-auto with a 223 chamber might not function reliably and long-term use could damage the gun. When was the last time you saw a semi-auto chambered in 223? The only one I'm aware of is the very early Ruger Mini-14's. Ruger quickly changed that so Mini owners didn't damage their rifles shooting surplus 5.56.

Just for perspective, there is a far greater difference in pressures, and even chamber dimensions between 30-06 rifles and ammo made in the last 100+ years. The 30-06 ammo my grandfather carried in WW-1 was a 150 gr bullet at 2700 fps. The ammo my father carried in WW-2 was a 150 gr bullet at 2800 fps. A typical modern factory load is a 150 gr bullet at 2900-3000 fps and there are some specialty loads as fast as 3100 fps. That's a wide range.

Most any 30-06 bolt rifle will handle any of those loads, but you do sometimes see enough difference in manufacturing tolerances to find some loads that cause problems in some rifles.

The Garand however was designed around the 2800 fps load. I've never heard of it causing a dangerous situation, but hotter loads will damage the rifle, and those loads are not recommended for other commercial semi-auto's in 30-06.

5.56 CAN be loaded to SLIGHTLY higher pressure than 223. But I seriously doubt that any commercially loaded ammo is going to be loaded right to the max. It is highly doubtful that you'll ever find 5.56 ammo that actually exceeds 223 pressure limits. If you handload and like to push the envelope maybe.

If your rifle has a 5.56 chamber either cartridge works fine. There is the potential of being overpressure if 5.56 is loaded in a 223 chamber. A bolt rifle is strong enough to easily handle this.

In the real world the only concern is that 5.56 fired in a semi-auto with a 223 chamber might not function reliably and long-term use could damage the gun. When was the last time you saw a semi-auto chambered in 223? The only one I'm aware of is the very early Ruger Mini-14's. Ruger quickly changed that so Mini owners didn't damage their rifles shooting surplus 5.56.

Just for perspective, there is a far greater difference in pressures, and even chamber dimensions between 30-06 rifles and ammo made in the last 100+ years. The 30-06 ammo my grandfather carried in WW-1 was a 150 gr bullet at 2700 fps. The ammo my father carried in WW-2 was a 150 gr bullet at 2800 fps. A typical modern factory load is a 150 gr bullet at 2900-3000 fps and there are some specialty loads as fast as 3100 fps. That's a wide range.

Most any 30-06 bolt rifle will handle any of those loads, but you do sometimes see enough difference in manufacturing tolerances to find some loads that cause problems in some rifles.

The Garand however was designed around the 2800 fps load. I've never heard of it causing a dangerous situation, but hotter loads will damage the rifle, and those loads are not recommended for other commercial semi-auto's in 30-06.