MoscowMike

New member

I have been looking for a Webley Mk VI for awhile and finally found one on Gunbroker that fit my price range, $425 plus shipping. The dealer said it was from an estate sale, had been shaved for .45, locked up tight, good bore, but he hadn't fired it.

It's parkerized, with some dings, but generally looks good. Marked 1916, the serial number is 1953xx.

When I picked it up at the FFL today, I noticed the double action pull was heavy, as expected, with the single action surprisingly light.

I also noticed that you could pull the hammer back completely, and in the last bit of movement it went past one click to another, at which point the hammer dropped on a few ounces of pull. Odd.

I had been wondering about whether it had been shaved enough to work with .45 auto rim cartridges or just those in moon clips, so I loaded it with empty ARs, and it dragged a bit, wouldn't rotate into lockup. That wasn't too surprising, some were shaved just enough for standard ACP cases in the moon clips. But, when I loaded standard .45 ACP empties into a moon clip and tried it, same issue, the cylinder wouldn't rotate smoothly into line with the bore. Not sure if it's a depth of cylinder cut issue or if the mechanism isn't rotating the cylinder with enough force.

The cylinder lockup tightness was reasonable when I first started fiddling with it, but after watching the cylinder both with cases and without, it seemed to hesitate more. Now the empty cylinder has locked up completely. The hammer is in the cocked position and the cylinder is a bit out of line with the bore. I haven't forced anything, just using normal pressure on the trigger and the hammer.

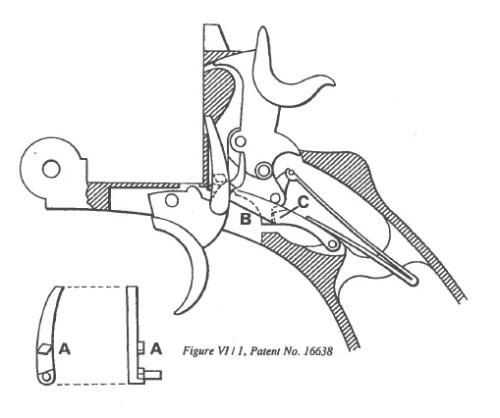

Because it's jammed, I can't really check the hand to see if it's binding and not pushing the cylinder correctly. And there is the odd single action issue.

I have a note out to the dealer and we'll see what he says, but I would prefer to fix it rather than see if he'll take it back.

Any suggestions for things to look for?

- Mike

It's parkerized, with some dings, but generally looks good. Marked 1916, the serial number is 1953xx.

When I picked it up at the FFL today, I noticed the double action pull was heavy, as expected, with the single action surprisingly light.

I also noticed that you could pull the hammer back completely, and in the last bit of movement it went past one click to another, at which point the hammer dropped on a few ounces of pull. Odd.

I had been wondering about whether it had been shaved enough to work with .45 auto rim cartridges or just those in moon clips, so I loaded it with empty ARs, and it dragged a bit, wouldn't rotate into lockup. That wasn't too surprising, some were shaved just enough for standard ACP cases in the moon clips. But, when I loaded standard .45 ACP empties into a moon clip and tried it, same issue, the cylinder wouldn't rotate smoothly into line with the bore. Not sure if it's a depth of cylinder cut issue or if the mechanism isn't rotating the cylinder with enough force.

The cylinder lockup tightness was reasonable when I first started fiddling with it, but after watching the cylinder both with cases and without, it seemed to hesitate more. Now the empty cylinder has locked up completely. The hammer is in the cocked position and the cylinder is a bit out of line with the bore. I haven't forced anything, just using normal pressure on the trigger and the hammer.

Because it's jammed, I can't really check the hand to see if it's binding and not pushing the cylinder correctly. And there is the odd single action issue.

I have a note out to the dealer and we'll see what he says, but I would prefer to fix it rather than see if he'll take it back.

Any suggestions for things to look for?

- Mike