Strength is kind of a relative thing. What do you mean by strength?

I consider an action strong in terms of how well it supports the case. The brass case is the weakest link in an action made of modern materials.

That in itself can be kind of a kicker: modern materials. All the time you read in this forum owners of pre WW1 rifles, M1891 Argentines making claims about how wonderfully strong their rifles are. They are basing this on shill gunwriter articles and appearances. These old rifles have wonderful precise machining. But precise machining does not mean the metal is worth a flip. Metallurgy was a developing science the first decades of the twenty century. They did not even have a definition or an understanding of cold temperatures and shock at the time of the Titanic sinking. Iron and steels were produced in period bloomeries

http://en.wikipedia.org/wiki/Bloomery, foundries, under process control conditions that by today’s standards, are shockingly primitive. Period metals are highly variable and data about period metals always show impurities and slag.

The steels used in these older military rifles were just plain carbon steels. The yield strength on this stuff is almost half of modern alloy steels. Today, unheated, the same steels are used in applications like rebar. No one today would make such a safety critical part, as a rifle receiver, from rebar. When one of these old plain carbon receivers blow, they frag. Plain carbon steel does not have the ductility of an alloy steel.

All Swedish rifle receivers are made from plain carbon steels. The Swedes were proud that they never changed their rifle receivers from plain carbon steels to alloy steels. This might be a cultural issue, the Vikings were extremely conservative by nature. Swedish iron , by geographic accident, had amazingly low amounts of phosphorous, and if the steel making process was well controlled, plain carbon steel made from Swedish iron was as good as you could get back then.

The high quality of Swedish steel and craftsmanship can make up a bit.

As you can see from this quote, the cultural memory of "Swedish steel" being a quality attribute is still within the community. Modern measurement , chemistry, and smelting processes make country or mine origin irrelvant in terms of iron quality and yet these echoes from a century past are still being passed around.

The best news is that your rifle was built in 1941. Metallurgy was a mature science by then. Process controls and the science of metallurgy advanced from 1920 to 1940 as rapidly as the semiconductor revolution did from 1980 to 2000. So your receiver is quite probably the best made M96 receivers ever made. And that is good.

The M96 is as “fully” as strong as any Mauser receiver made. Gunwriters have been poo pawing the things for decades, without understanding why SAAMI loading are lower for the things, but then they are at best, French majors. But eyeballing the locking lug size, receiver seat thicknesses, these things are sized the same as the M98 actions. (Honestly, I have only eyeballed them, I suspect the difference in thickness between a M96 and a M98 lug is thousandth’s of an inch) Structurally it should take the same amount of force to shear a carbon steel M96 lug as a carbon steel M98 lug.

But what the M98 has that the M96 does not have is a better and safer design. The M98 is the best overall action ever designed. It is the best balance of safety, strength, reliability, maintainability of any bolt action ever made.

If a case head fails, the M98 offers better shooter protection through shrouding, gas ventilation. Not to throw too many rocks at the M96 because many modern actions offer the shooter the same low protection levels as a M96. (Something never mentioned by shill gunwriters) The M70 comes to mind. The gas venting in a M70 is awful, gases come right down the firing pin shaft into your eye. However M70 seldom blow because they are built from 4140 steel.

I would load your rifle without worrying about a structural failure of the action. I would be cautious to always use best quality brass, would advise not to hot load the thing, just stay within Swedish military ammo pressures and velocities, and I would always wear eyeprotection, just in case you have a gas leak.

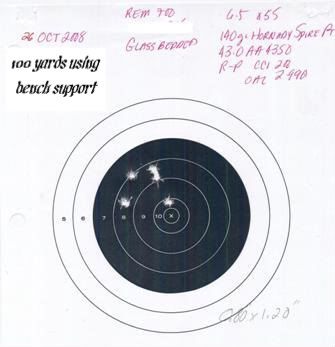

I don’t know the story, but the picture tells a lot.

Here is some of my data, for reference in developing your loads. I think a 140 Hornaday with 43 grains of 4350 is equivalent (a little to the high side) of the Swedish service round.

Code:

[SIZE="3"]M1896 Infantry Rifle 29' barrel Carl Gustafs mfgr 1903

17-Aug-06 T = 85 °F

143 gr FMJ 1986 Swedish Ball

Ave Vel = 2610

Std Dev = 14.38

ES = 45.59

High = 2633

Low = 2587

N = 8

M38 Infantry Carbine 24" barrel

28-Oct-94 T ≈ 60 °F

143 gr 1986 Swedish Ball OAL 3.065" 47.4 grs powder average

Ave Vel = 2427

Std Dev = 22

ES = 62

Low = 2395

High = 2457

N = 10

M700 22" Barrel

143 gr Swedish Ball 1986 headstamp

2 Feb 2008 T = 54 °F

Ave Vel = 2470

Std Dev = 18

ES = 48

High = 2491

Low = 2443

N = 5

140 gr Hornday Spire Point 43.0 grs AA4350

R-P new brass CCI-200 OAL 2.990"

2 Feb 2008 T = 52 °F

Ave Vel = 2512

Std Dev = 27

ES = 72

High = 2547

Low = 2475

N = 5[/SIZE]