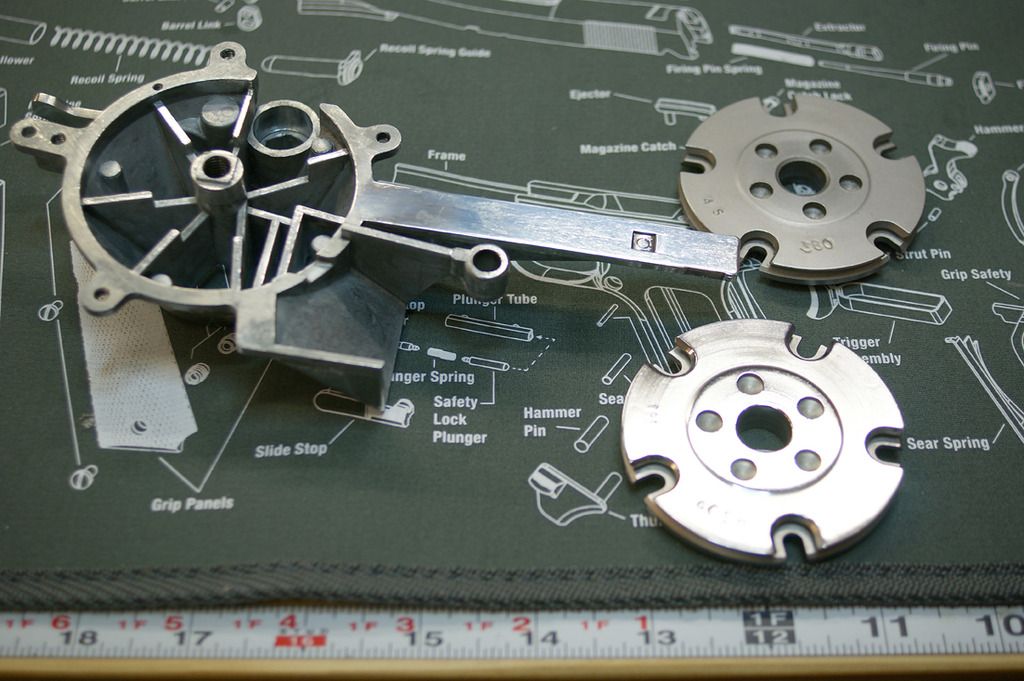

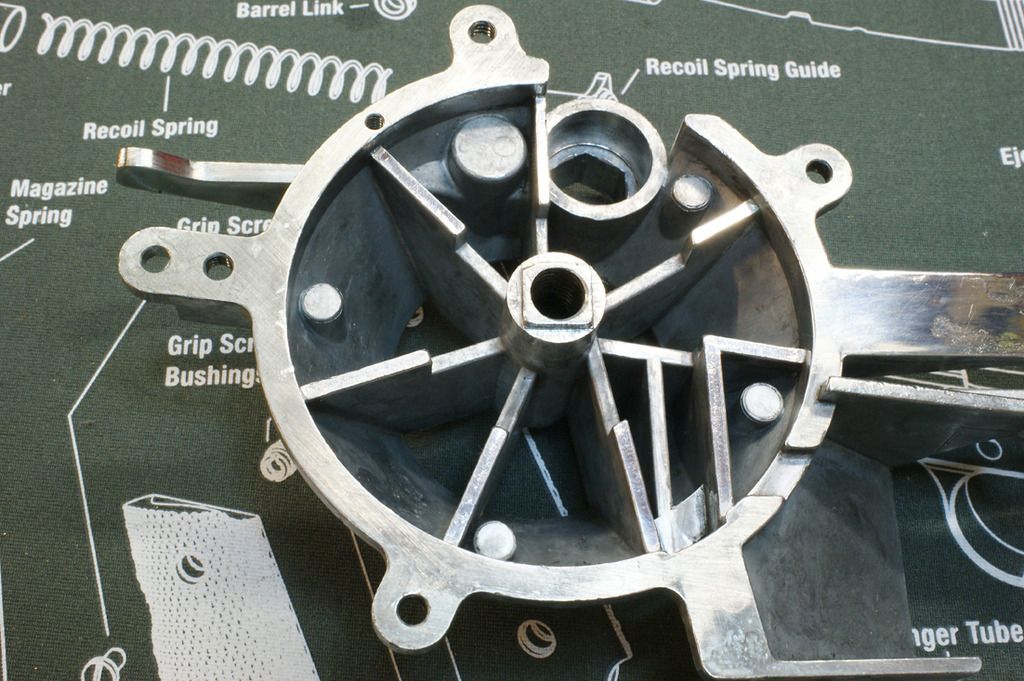

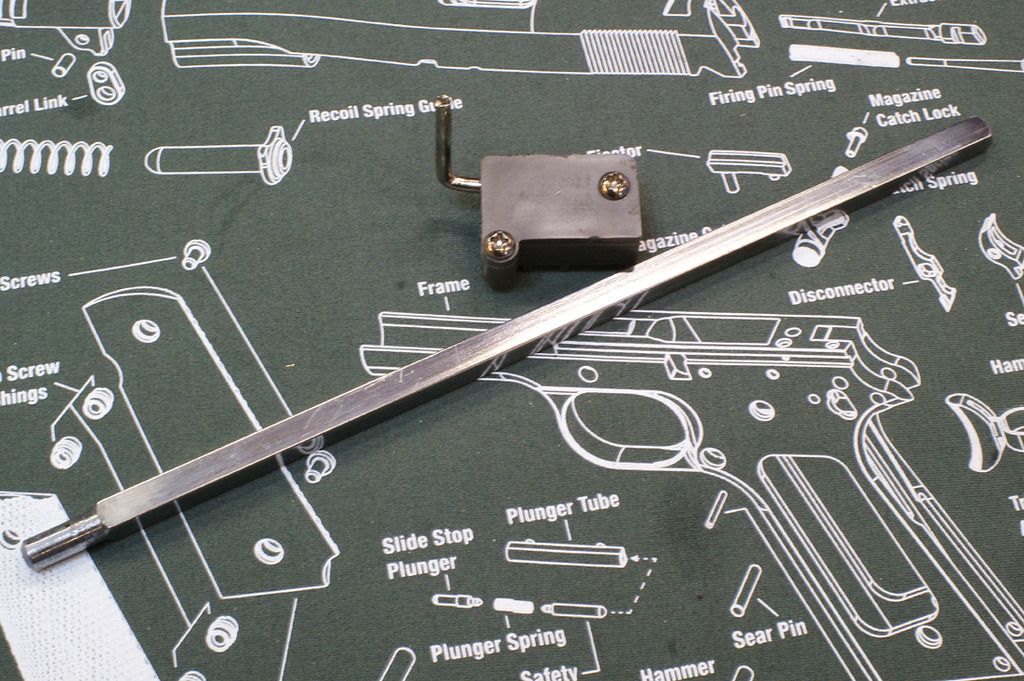

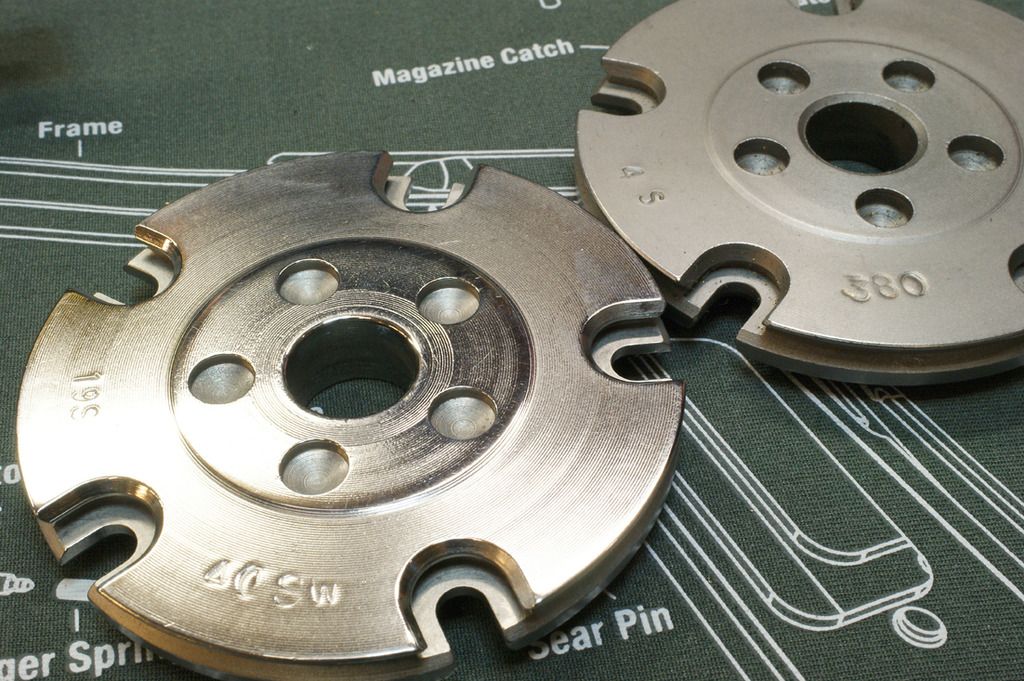

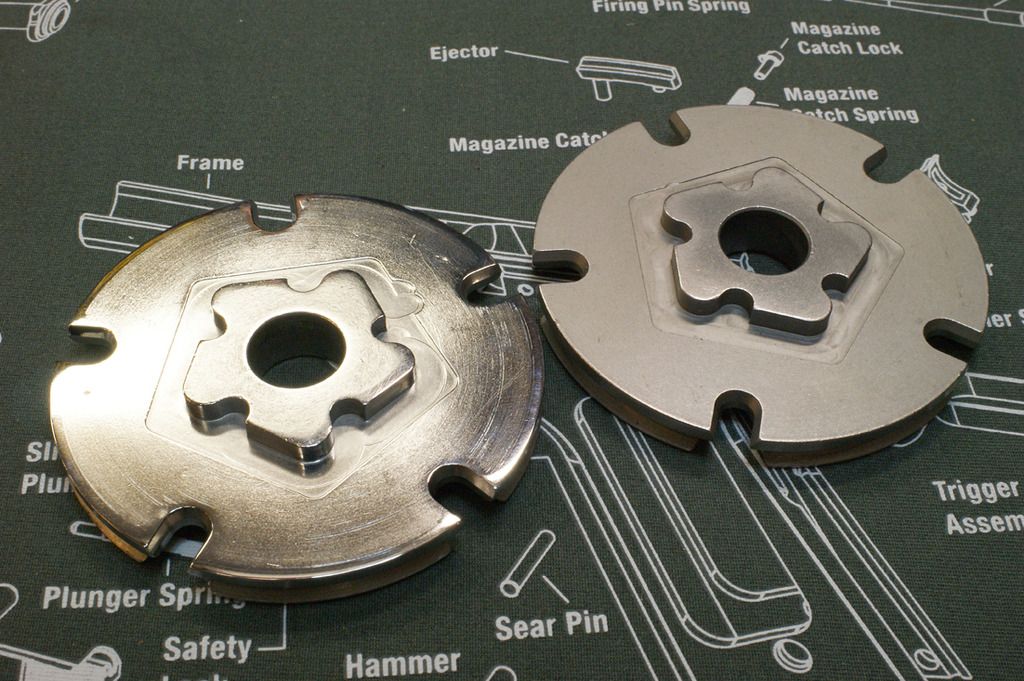

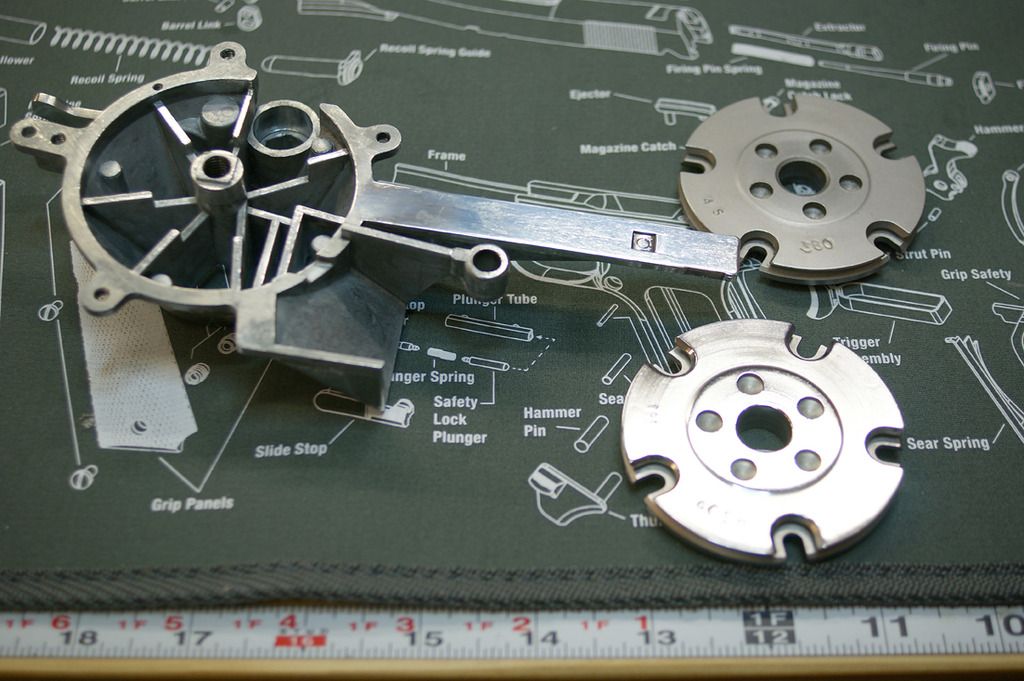

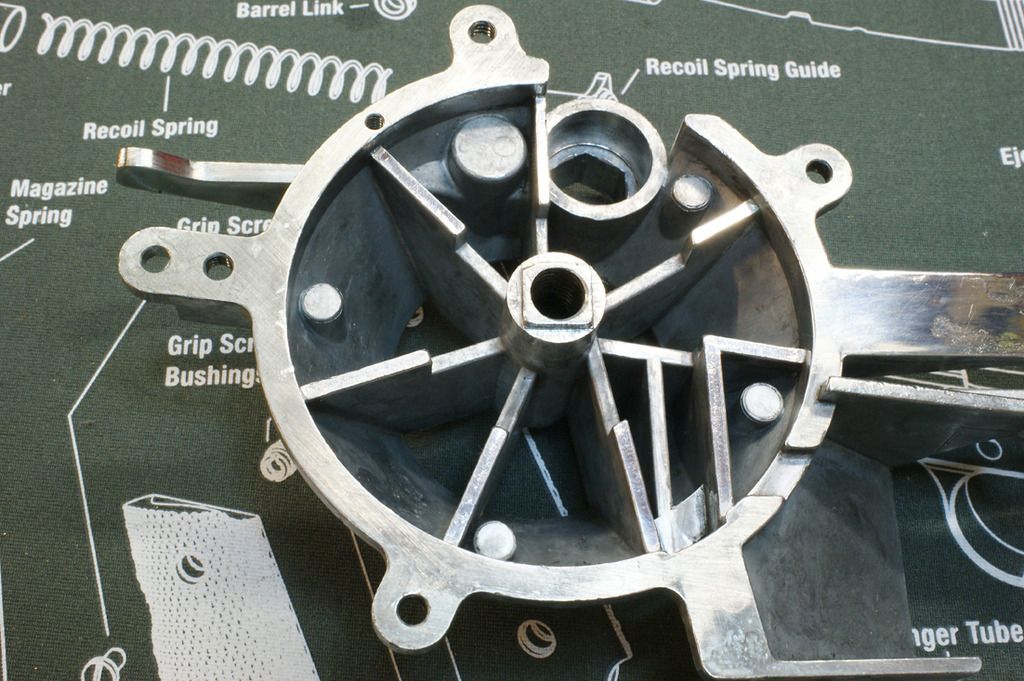

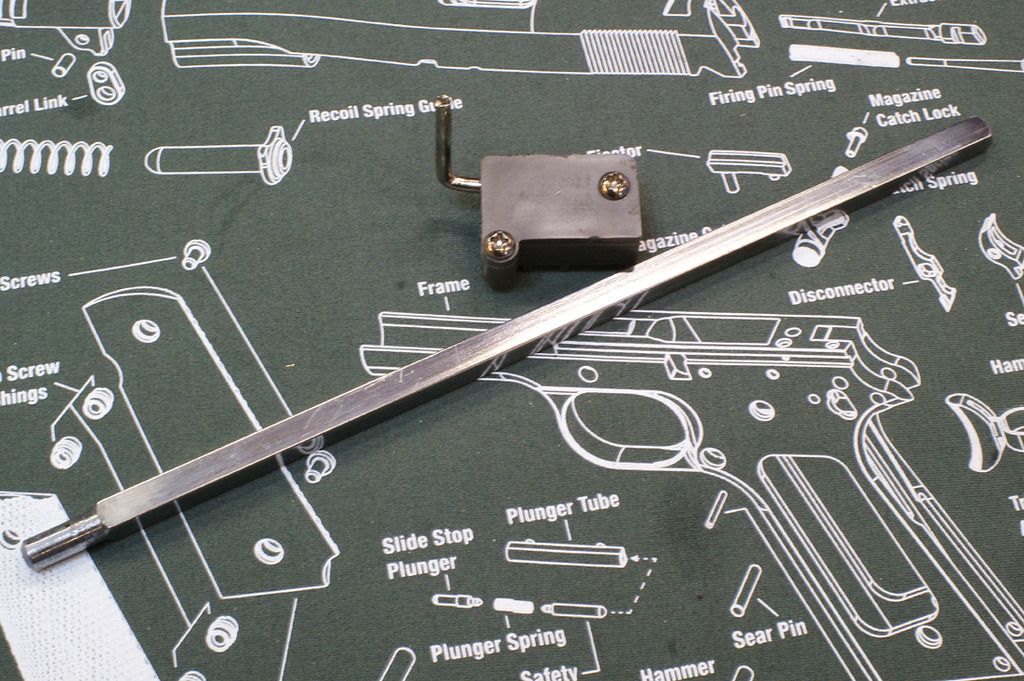

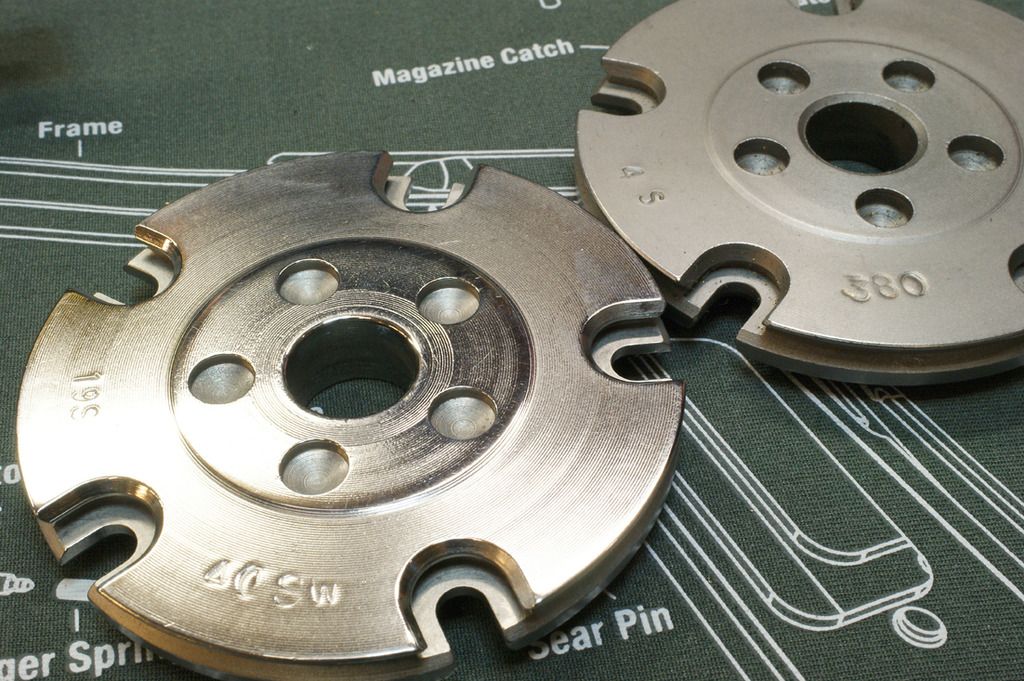

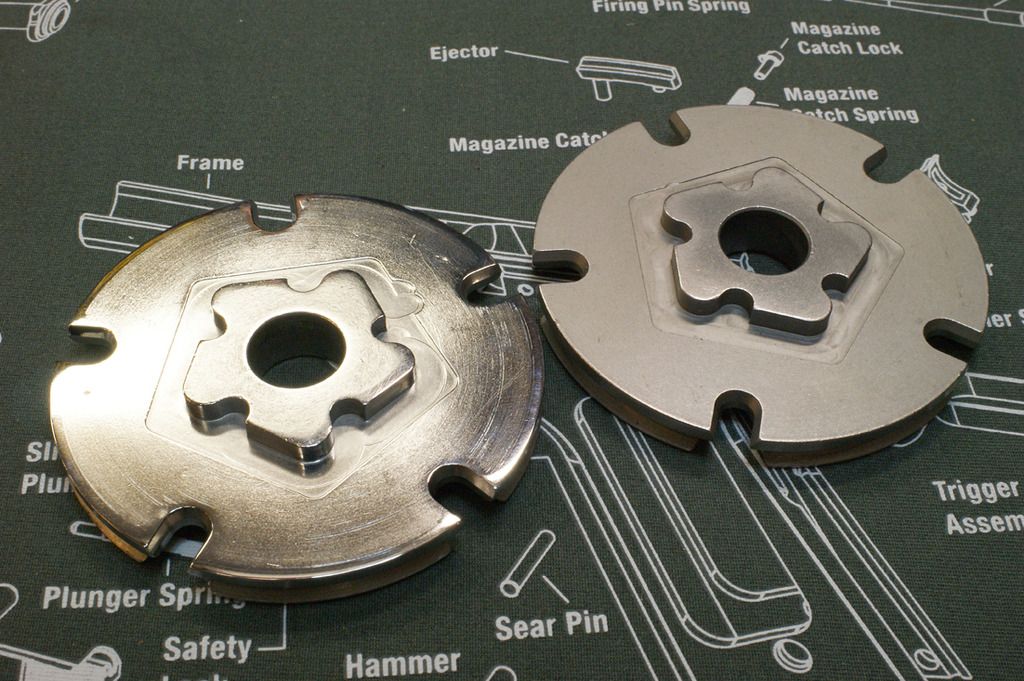

Hey all, I just got my carrier & primers back from MagicMike... and WOW!!! So I took it to the next level by polishing the carrier ribs, case feed parts and shell plates. In the pix that follow you'll see what I did. It's hard to see the carrier ribs, but MagicMike milled those flat and I hit them with some Dremel polishing pads & rouge. With the slider ramp I used a bench-buffer w/6" polishing wheels and 3 different grits of rouge... and I could see my teeth in its reflection. I hit all the edges and the underside as well, using the Dremel. Also polished the case feed slider & bar, no lube necessary! Same on both sides of the shell plate (a stock, unpolished .380 plate shown next to my polished .40), except I first hit those with 1000 & 2000 wet sandpaper. End result: When I sit the plate loose on the carrier it will spin like its on bearings. Just say no to friction!

Last edited: