PID means;PID stands for Proportional, Integral, Derivative. Controllers are designed to eliminate the need for continuous operator attention.

They are a tiny microprocessor, that is a fancy thermostat. I was unhappy with the wide temperature swings on my lee 20# pot. Besides I love to tinker and challenge new technology. I darn near bit off more than I could chew! Took me over a week to make sense of the directions that came with the PID! Turns out I had the PID programmed right, just had the polarity of the SSR,(Solid State Relay), bassackwards!

Turns out I had the PID programmed right, just had the polarity of the SSR,(Solid State Relay), bassackwards!

Anyway here's some pics,,,---you didn't really think there wouldn't be pics???¿

That's the PID. Not seated all-the-way-in yet, I'll fix that before putting the cover on.

That's the heat sink, I was told I needed one, well I'm only drawing maybe 6 amps through a SSR capable of 40 amps, it doesn't even get warm!

On-off switch and the cover's laying on top.

Thermocouple in the bottom of the pot, it senses directly into the molten lead.

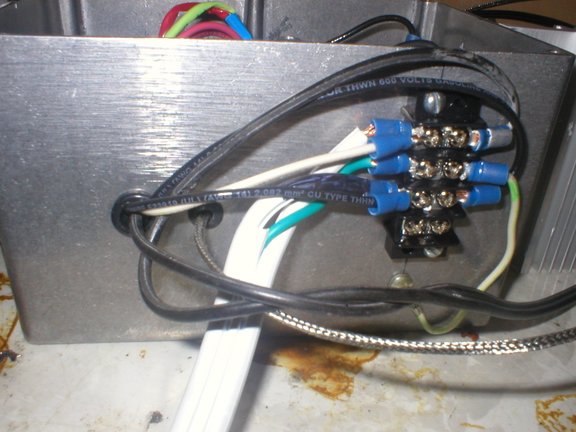

Wiring terminal block, on the outside where it's easier to hook up.

BBS can't count, says I had 7 pics, I dunno, I only counted 6-------.

Overkill? Maybe, but it's cool factor is off the chart! It's neat to see it react to temp changes, like dipping a mold in the melt to warm it up, then see the PID react instantly to try to raise the heat, and see the readout in degrees. Or see the temp instantly drop when you drop some cooled sprues into the pot. The heat, or in this case cold, travels fast in the melt!

They are a tiny microprocessor, that is a fancy thermostat. I was unhappy with the wide temperature swings on my lee 20# pot. Besides I love to tinker and challenge new technology. I darn near bit off more than I could chew! Took me over a week to make sense of the directions that came with the PID!

Anyway here's some pics,,,---you didn't really think there wouldn't be pics???¿

That's the PID. Not seated all-the-way-in yet, I'll fix that before putting the cover on.

That's the heat sink, I was told I needed one, well I'm only drawing maybe 6 amps through a SSR capable of 40 amps, it doesn't even get warm!

On-off switch and the cover's laying on top.

Thermocouple in the bottom of the pot, it senses directly into the molten lead.

Wiring terminal block, on the outside where it's easier to hook up.

BBS can't count, says I had 7 pics, I dunno, I only counted 6-------.

Overkill? Maybe, but it's cool factor is off the chart! It's neat to see it react to temp changes, like dipping a mold in the melt to warm it up, then see the PID react instantly to try to raise the heat, and see the readout in degrees. Or see the temp instantly drop when you drop some cooled sprues into the pot. The heat, or in this case cold, travels fast in the melt!