A quick background: This is a review I have been working on for the forums for a few months now. One of many of my professional shooting responsibilities these days is that I work as a R&D for a Ammunition Laboratory. We develop every kind of ammunition mainly for LE and Military application. I had to ask permission to do this review and it had to be released as not to give away any sensitive or proprietary information. Good news is that with all the R&D for LE and Military, there will also be similar consumer lines closely mirroring the Pro stuff. Obviously the consumer wont get the very specialty stuff directly designed for the Military but from evaluating both, the consumer gets a very similar product. Here is the review:

Part 1

Non lead ammo and the future of ammunition development:

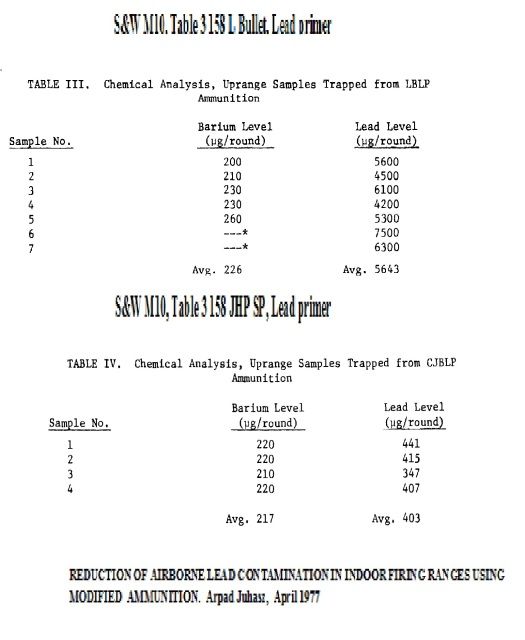

The future of ammunition isnt that hard to predict. The EPA as well as other outside forces have imposed their concerns on the ammunition industry for awhile now. The outrageous expense of lead clean up at public and private ranges have close many. A lot of this depends on which state you live in. That said, my concerns about my ammo are that it is reliable and accurate. I don’t want to seem insensitive to the environment but my heart is all about performance. I am all for non-lead bullets providing they equal or better the current high performance lead based ammo. I think those days are here. I have been involved with testing some very interesting ammunition for Law Enforcement and Military application over the last few months. There is also a consumer line that mirrors most of the LE/ Military version and this makes sense because of all the R&D in this kind of ammunition is expensive. I was allowed to do this review through the Ammunition Laboratory as long as I did not give any proprietary secrets so I will give a general review and most of all the ammo pictured is from the consumer line. LE and Military have certain specs they require for the bullets of tomorrow. What this means is that their specs will become the standard of ammo for the general public.

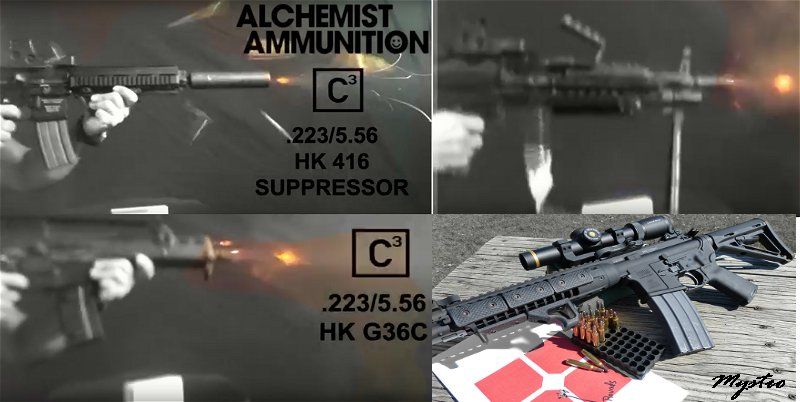

The Test Firearms and Caliber: As with most LE and Military testing, there are certain platforms that are required. I am testing with the required firearms as well as others not on the list.

My test firearms are: Sig Sauer P226, P229, P220, P227 Glock 17,19, 23, M&P 45, 380, Walther PPQ 9mm, PPQ 45, PPK, HK USP, HK USP Compact, LWRC M6 iC, HK416. The Calibers being evaluated are 380, 9mm, 38spl, 357 Sig, 40S&W, 45acp, 5.56, 7.62, 300 BLK.

The AMMO:

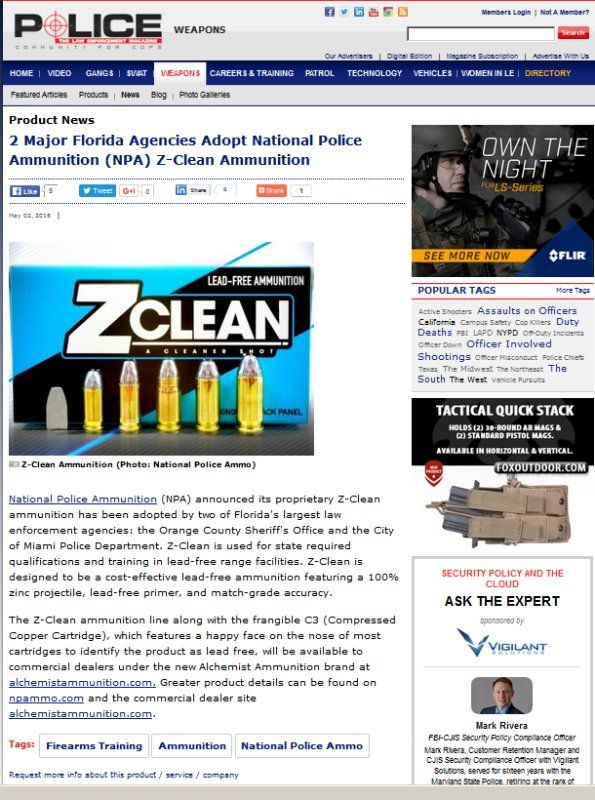

There are two non lead bullets being tested. A Zinc general range and mil spec bullet to replace the lead based fmj. This would be used as a range and mil-spec duty round. It is currently called “Zclean” in its consumer name. Its main component is zinc as well as other proprietary compositions.

The next is a compressed copper Frangible. It is currently labeled as a “Alchemist C3 round” for non-LE sale. This is used as training rounds for CQB, door breaching, hostage rescue, etc. Some may know these training areas as the “kill house”. These enclosed areas have hard walls such as cinder blocks and other real world hard surfaces where ricochets and “bounce backs” are extremely dangerous with conventional ammo. Air quality is also a factor and there are guidelines that must be met. Cheaper alternative frangible ammo was known to create a high content of airborne silica. The Alchemist are engineered to stay well within the guidelines. The last performance factor that has been associated with frangible bullets are the content of iron. These older types of frangible bullets have been known to spark when hitting steel plates and cause range fires. The Alchemist and their LE counter parts have eliminated the spark issues with not having any iron in them. As you can see there are a lot of factors that go into a modern frangible. Both types of ammo use a sealed non lead primer that does not absorb moisture. This gives them a very long shelf life that most military ammo is known for.

Zclean (non lead bullet) testing:

I will first start with the Zclean ammo since this will be the most popular for myself and most shooters. I quickly found many benefits of this kind of bullet for the average shooter. First, as the name implies, it is actually very clean to shoot. Shockingly so that after 500 rounds of shooting through many different platforms of firearms, all remain cleaner than what they would have been with a quality lead fmj.

Obviously cleaner ammo means less cleaning for the LE or soldier in the field as well as the serious shooter that takes extended tactical classes. Next is the inherent accuracy. Groups are as good or better than what I typically get with premium ammunition like HST or Gold Dot. I actually used several calibers of HST as the control round to compare against.

Because it is not a lead round, bullet weights of the Zinc bullets are different than their lead counter parts but poa/poi are the same. For example 9mm ='s 100 grain, 40S&W='s 125 grain, 45acp='s 155 grain, etc.... I tested the rifle zinc rounds but at this time only the pistol calibers are ready for prime time release.

The ammo with its truncated design inherently feeds better and has functioned flawlessly with all firearms tested.

The Zink bullets has not created any issue with any build up in either conventional or polygonal rifling. They also have a lubed characteristic between the bullet and barrel from the zinc. This is kind of a added benefit not foreseen at the beginning of the testing. At this point with 1000s of rounds I have shot, I see no down sides to this bullet. There was only one issue brought up to me and its either a positive or negative quality depending if you are using this as a practice round or NATO military replacement. It penetrates better than the conventional FMJ. This means it may ricochet (or penetrate) with poorly designed steel bullet traps. Some may see a tactical advantage for these characteristics, especially the military. Both of the “Alchemist” frangible and “Zclean” zinc ammo ran flawlessly in full auto weapons that they were tested. I can confirm there were many more than the ones mentioned above.

Due to limited space : See Part 2 for the rest of the review

Part 1

Non lead ammo and the future of ammunition development:

The future of ammunition isnt that hard to predict. The EPA as well as other outside forces have imposed their concerns on the ammunition industry for awhile now. The outrageous expense of lead clean up at public and private ranges have close many. A lot of this depends on which state you live in. That said, my concerns about my ammo are that it is reliable and accurate. I don’t want to seem insensitive to the environment but my heart is all about performance. I am all for non-lead bullets providing they equal or better the current high performance lead based ammo. I think those days are here. I have been involved with testing some very interesting ammunition for Law Enforcement and Military application over the last few months. There is also a consumer line that mirrors most of the LE/ Military version and this makes sense because of all the R&D in this kind of ammunition is expensive. I was allowed to do this review through the Ammunition Laboratory as long as I did not give any proprietary secrets so I will give a general review and most of all the ammo pictured is from the consumer line. LE and Military have certain specs they require for the bullets of tomorrow. What this means is that their specs will become the standard of ammo for the general public.

The Test Firearms and Caliber: As with most LE and Military testing, there are certain platforms that are required. I am testing with the required firearms as well as others not on the list.

My test firearms are: Sig Sauer P226, P229, P220, P227 Glock 17,19, 23, M&P 45, 380, Walther PPQ 9mm, PPQ 45, PPK, HK USP, HK USP Compact, LWRC M6 iC, HK416. The Calibers being evaluated are 380, 9mm, 38spl, 357 Sig, 40S&W, 45acp, 5.56, 7.62, 300 BLK.

The AMMO:

There are two non lead bullets being tested. A Zinc general range and mil spec bullet to replace the lead based fmj. This would be used as a range and mil-spec duty round. It is currently called “Zclean” in its consumer name. Its main component is zinc as well as other proprietary compositions.

The next is a compressed copper Frangible. It is currently labeled as a “Alchemist C3 round” for non-LE sale. This is used as training rounds for CQB, door breaching, hostage rescue, etc. Some may know these training areas as the “kill house”. These enclosed areas have hard walls such as cinder blocks and other real world hard surfaces where ricochets and “bounce backs” are extremely dangerous with conventional ammo. Air quality is also a factor and there are guidelines that must be met. Cheaper alternative frangible ammo was known to create a high content of airborne silica. The Alchemist are engineered to stay well within the guidelines. The last performance factor that has been associated with frangible bullets are the content of iron. These older types of frangible bullets have been known to spark when hitting steel plates and cause range fires. The Alchemist and their LE counter parts have eliminated the spark issues with not having any iron in them. As you can see there are a lot of factors that go into a modern frangible. Both types of ammo use a sealed non lead primer that does not absorb moisture. This gives them a very long shelf life that most military ammo is known for.

Zclean (non lead bullet) testing:

I will first start with the Zclean ammo since this will be the most popular for myself and most shooters. I quickly found many benefits of this kind of bullet for the average shooter. First, as the name implies, it is actually very clean to shoot. Shockingly so that after 500 rounds of shooting through many different platforms of firearms, all remain cleaner than what they would have been with a quality lead fmj.

Obviously cleaner ammo means less cleaning for the LE or soldier in the field as well as the serious shooter that takes extended tactical classes. Next is the inherent accuracy. Groups are as good or better than what I typically get with premium ammunition like HST or Gold Dot. I actually used several calibers of HST as the control round to compare against.

Because it is not a lead round, bullet weights of the Zinc bullets are different than their lead counter parts but poa/poi are the same. For example 9mm ='s 100 grain, 40S&W='s 125 grain, 45acp='s 155 grain, etc.... I tested the rifle zinc rounds but at this time only the pistol calibers are ready for prime time release.

The ammo with its truncated design inherently feeds better and has functioned flawlessly with all firearms tested.

The Zink bullets has not created any issue with any build up in either conventional or polygonal rifling. They also have a lubed characteristic between the bullet and barrel from the zinc. This is kind of a added benefit not foreseen at the beginning of the testing. At this point with 1000s of rounds I have shot, I see no down sides to this bullet. There was only one issue brought up to me and its either a positive or negative quality depending if you are using this as a practice round or NATO military replacement. It penetrates better than the conventional FMJ. This means it may ricochet (or penetrate) with poorly designed steel bullet traps. Some may see a tactical advantage for these characteristics, especially the military. Both of the “Alchemist” frangible and “Zclean” zinc ammo ran flawlessly in full auto weapons that they were tested. I can confirm there were many more than the ones mentioned above.

Due to limited space : See Part 2 for the rest of the review