GARY... thanks for the picture...

seems like it rained most of the weekend, but I did get the chance to shoot a little, & the gun functioned perfectly... all the ammo seemed to be in the range I was looking for, with most being a bit light, & sooting the case body, with little to no swelling at the case web so a couple of them, I'll be working the charge up... the 13 Grains of Trailboss, shot clean, & were just beginning to swell the web, I won't go more than that

1st issue, & resolution... the brass... I bought 200 Hornady 460 S&W cases... none appeared to have been annealed, & while belling the 1st 12 rounds to test powders, a couple case mouths cracked... so on Sunday I took a cake pan, filled it half full of water, lined the cases up, & heated the mouths with my propane torch for 15 seconds each, then tipped them over in the water bath... got the familiar discoloration around the mouth...

2nd issue, & resolution... my Lee 460 S&W dies were purchased recently, & I'm not a huge fan of their o-ring locking nuts... well, I suspect the dies were made during the last big buying rush, as there are burrs on the threads... these will work themselves out, but the burrs make screwing the dies in to the press the same place difficult, as the locking nuts turn easier than the dies screw into my press, this was compounded by loading only 3 cartridges at a time, with 4 different powders... so, I ordered extra Redding locking rings to put on these dies... & as it is, after screwing in the dies 3-4 times, most of the burrs were off the threads by the end of my 1st loading session...

3rd issue & resolution... after about 10 rounds fired, the end of extractor tube cracked off, where the dog leg in the slot, that keeps the thumb tab tight against the barrel, & the screw at the end are closest... my buddy felt bad, he thought he probably shouldn't have used stress proof steel... since he had to drill the inside bigger to fit the 22 Magazine spring that he used in the extractor, & the thumb tab was bigger & heavier than other conversions he's done... so, he took the gun back home with him that day, & was going to order a tougher alloy for the tube, slightly larger diameter, so it wouldn't be so thin, & extend the tube another 1/8 - 3/16's inch, so the thinnest part would be thicker, & then skeletonize the thumb tab, to take some of the weight off it, so there would be less momentum under recoil... I should have it back by this week's end

over all, the gun shot well, & since it was pouring outside, target shooting wasn't the goal, but I did shoot at the top of a cement bag, that was plastered to a small hill in the yard, that had blown there over the winter, about 50 ft from my patio roof, & was able to hit it several times... it was expected, that I would need to file the front sight down ( front sight is a dovetailed Remington revolver sight ) but it looks to be pretty close now, probably won't need much filing... we discussed black powder loads, & I think I'm confident devoting 50 of my cases to black powder use... otherwise, I'm going to bump the Unique load up a grain or two yet, & probably pull the Trailboss back to 12.5 grains & see how accuracy looks, the 4198 loads looked pretty good, & I will go up one more grain, & see where we are at for accuracy there & adjust... I've decided not to include PB, even though it shot well, only because I've heard they are discontinuing that powder, & no sense developing a load for a new gun, that the powder is going away... I'm not a huge fan of loads that could be double or triple charged, like the Unique load could in that case, & even though it functioned fine, with the powder shaken up to the bullet, or spread level, or knocked into the base, it would have to be much more accurate than the Trailboss or 4198 for me to justify using it, because of it's low load density...

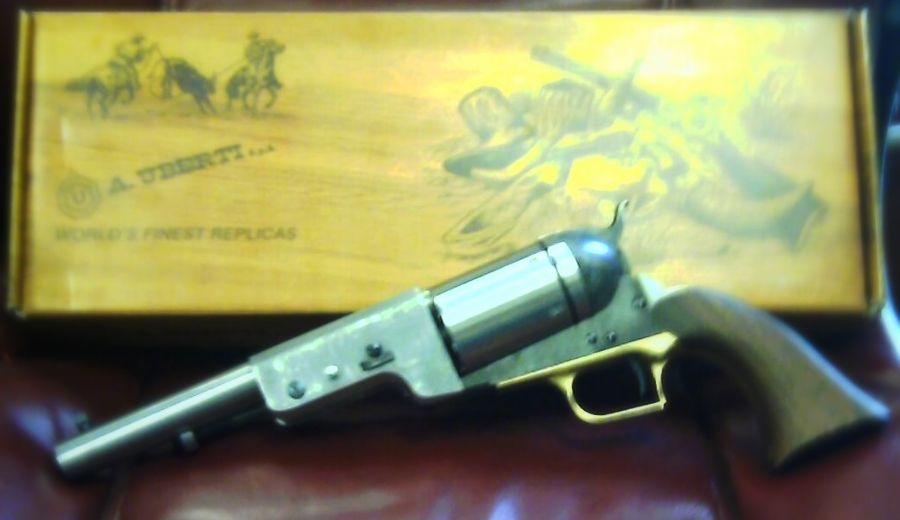

BTW... as far as finish on the metal... right now I'm leaning towards a low gloss blue, with nickel grip frame & cylinder... but again, I'll have all summer to decide...