I am just getting into casting.

I got started with crappy Lee molds, an old (rusty) dutch oven, and a turkey fryer. (It doesn't take as much heat as you think, to smelt/melt lead -- on a 20 lb propane tank, I can run the fryer for about a week, at smelting/casting temperatures; in contrast to about 6 hours for frying turkeys.)

Here, let me give you a break down of how I got started: (the local thrift store didn't make much off me, but I was happy about finding the pans and spoons.)

Pans for pan lubing and collecting dross - $4

Metal spoons for skimming dross - $2.50

Dutch oven - Free (from Crankylove)

Turkey fryer - Free (I use it for turkeys, catfish, and crawfish

)

Propane - about $6 per session (roughly $1.86 / lb, I believe)

SPG bullet lube - $15 per half-brick (I have since gone to

White Label Lubes, which are better,

and cheaper.)

Lee 429-200-RFP mold - $18

Lee .430 Sizer - $19

Rowen 1 lb dipper - $24

For $82.50, I was ready to take my own cast bullets from scrap/ingot to being fired again.

(The prices on the mold, sizer, and dipper can be beaten, too.)

There was a complication for me, though. I bought another Lee mold, the .429-310-RFP, for my .444 Marlin. It has a barrel with a .428" bore and .432" grooves. That means the .430" sizer won't work. The mold has two very different cavities, though (Lee molds aren't exactly top of the line). One cavity drops a bullet at .430" x .432", and the other cavity drops a bullet at .434" x .439". For now, the 'little' guy just gets tossed back into the pot. but, the big guy needs to be sized to fit in my chamber.

To size them, I have two choices:

1. Buy a luber/sizer. ~$200 to get set up. ...not gonna happen right now.

2. Find some one that makes custom push-through sizing dies. CH4D takes too long (and wants $66+), but Ranch Dog Outdoors sells a $15 .432" custom Lee sizer, that they (he) have produced in batch quantities.

The Lee molds do suck. They're sloppy, unfinished, unpredictable, and ugly. But they're cheap, easy to use, easy to locate, readily available, and make it fairly easy to produce half decent bullets. For 95% of shooters, a Lee mold is MORE than they will ever need.

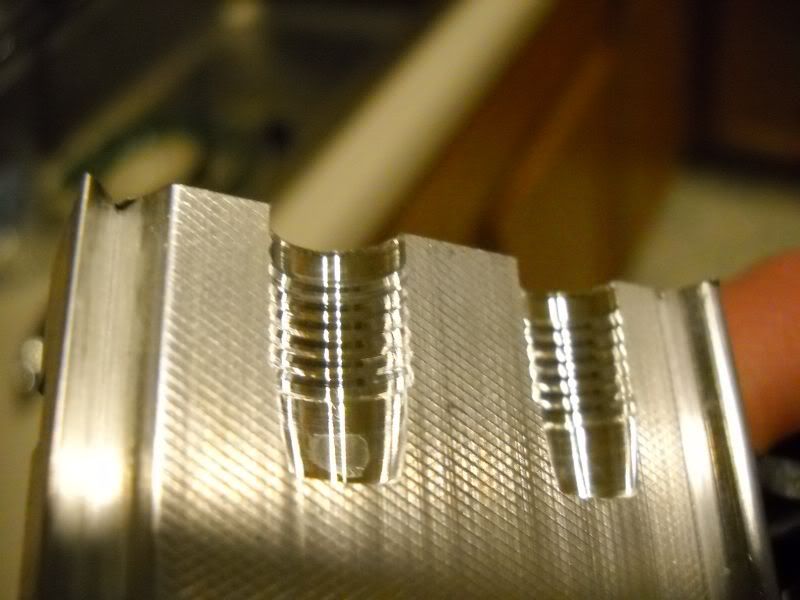

Tonight, I was casting some .315" 115 gr HPs from my NOE 314316 FPGC/HP mold ($107,

without handles). But, I kept over heating it. To kill the time while waiting for the mold to cool, I was casting some more of the Lee 429-200-RFPs, because it's just so quick and easy to cast usable bullets with that mold. (The 429-200 mold actually has a significant alignment issue, that requires me to align the mold with my hands for each pour; but it heats up quickly and kicks out good bullets in no time at all.)