One thing I hear much is: I have no time to cast. At times I can relate. Monday evening found a need for 1000 Lyman 429421 bullets to leave here this week, pretty simple stuff. Well my part time boss called Monday evening also. He needed someone to run an air hammer. The place I was going I’d hammered before so I knew it could be several days’ work. This means I’ll have to cast after work.

Soooooooo came home Tuesday, turned the pot on, filled it with sprues & set the moulds on top. Next, let the dogs out, fix the fire & pour a large glass of water.

Once the lead was up to temp it’s only a few rounds with the moulds & they were also hot. For this session we did the three mould rotation, two 429421 moulds & on 358156, all 4 cavity. Two short sessions, one Tuesday evening & one this evening did the trick with 1300ea. 44s & 700ea. 38s.

The moulds

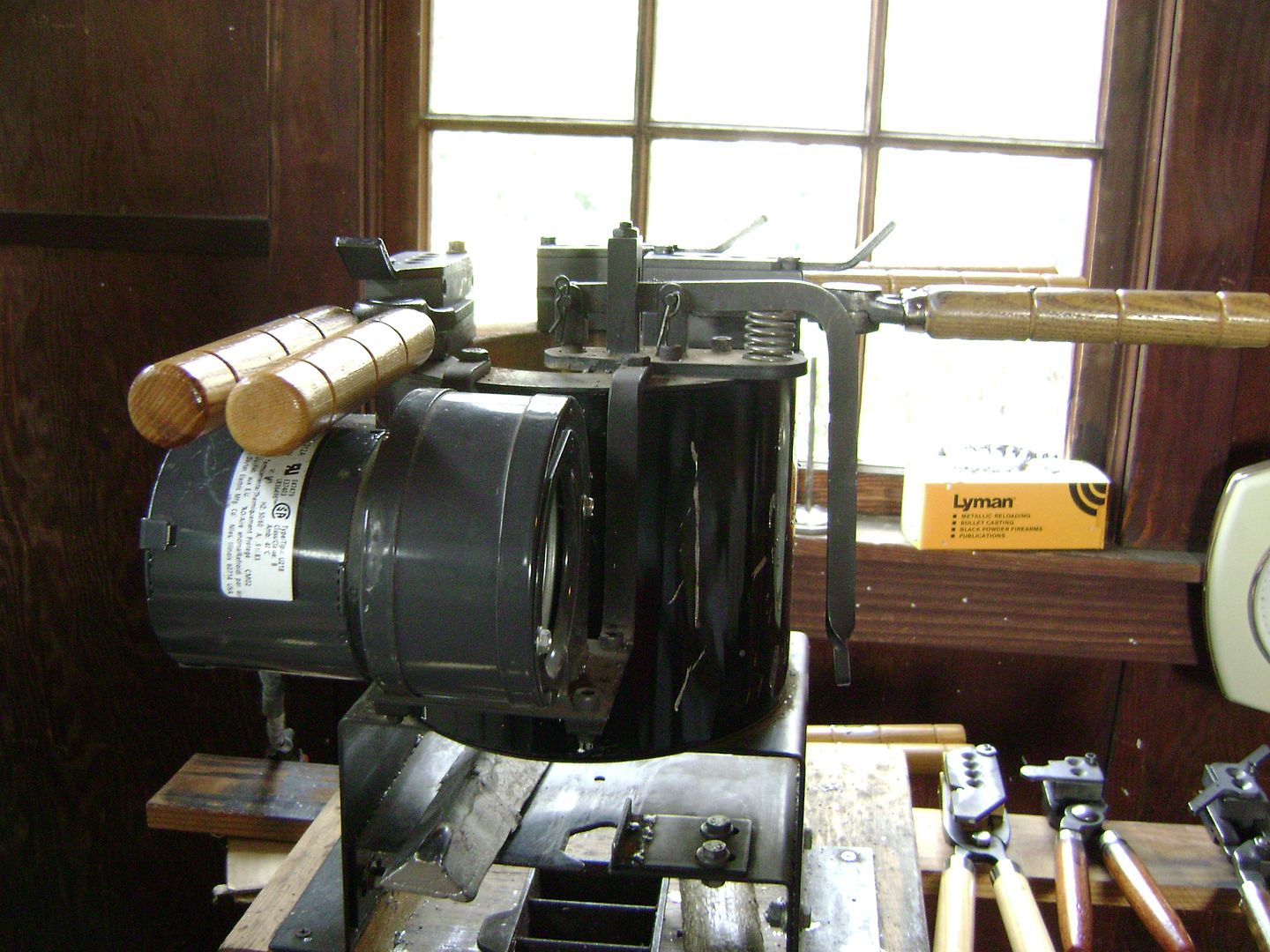

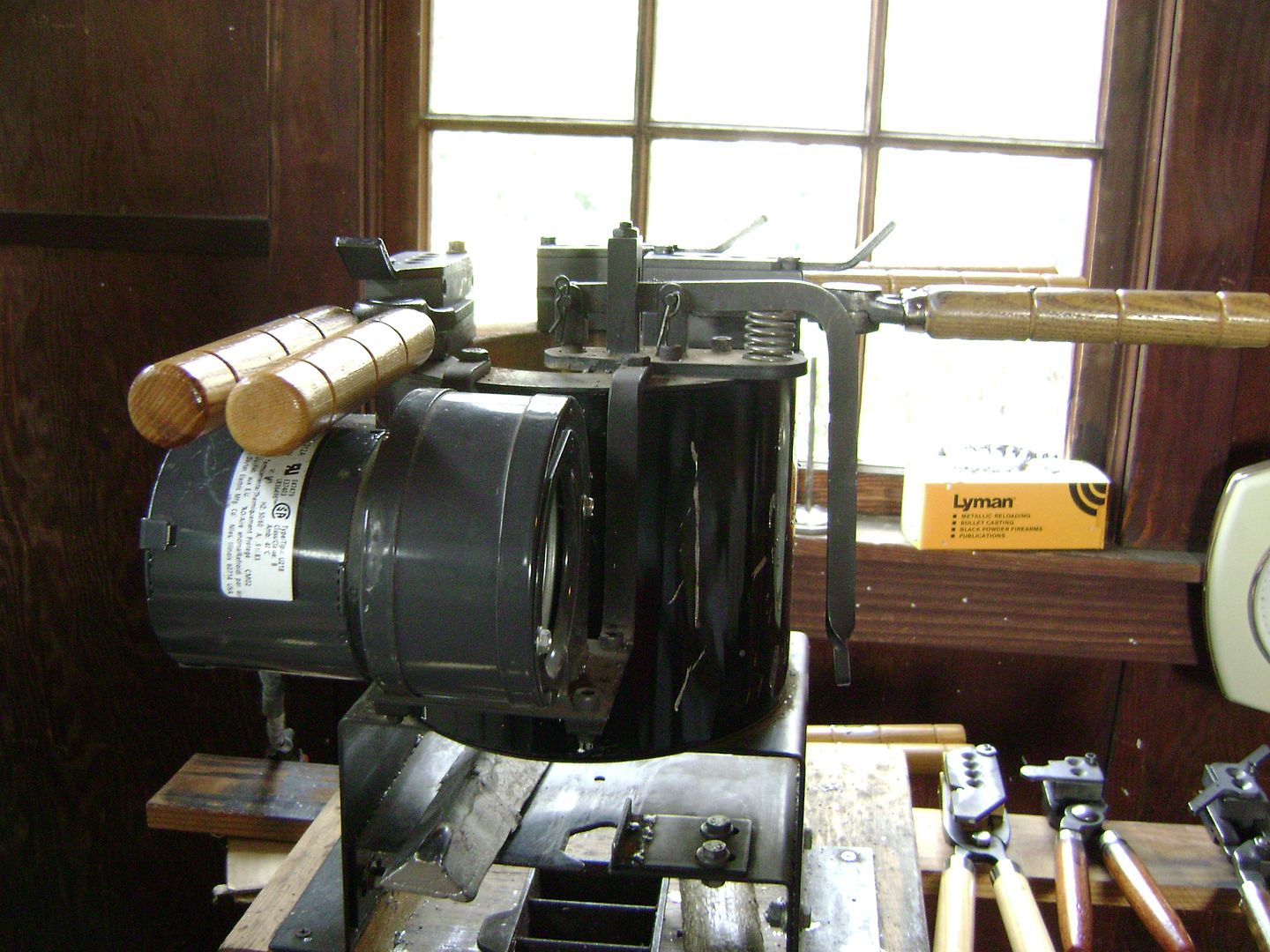

The pot

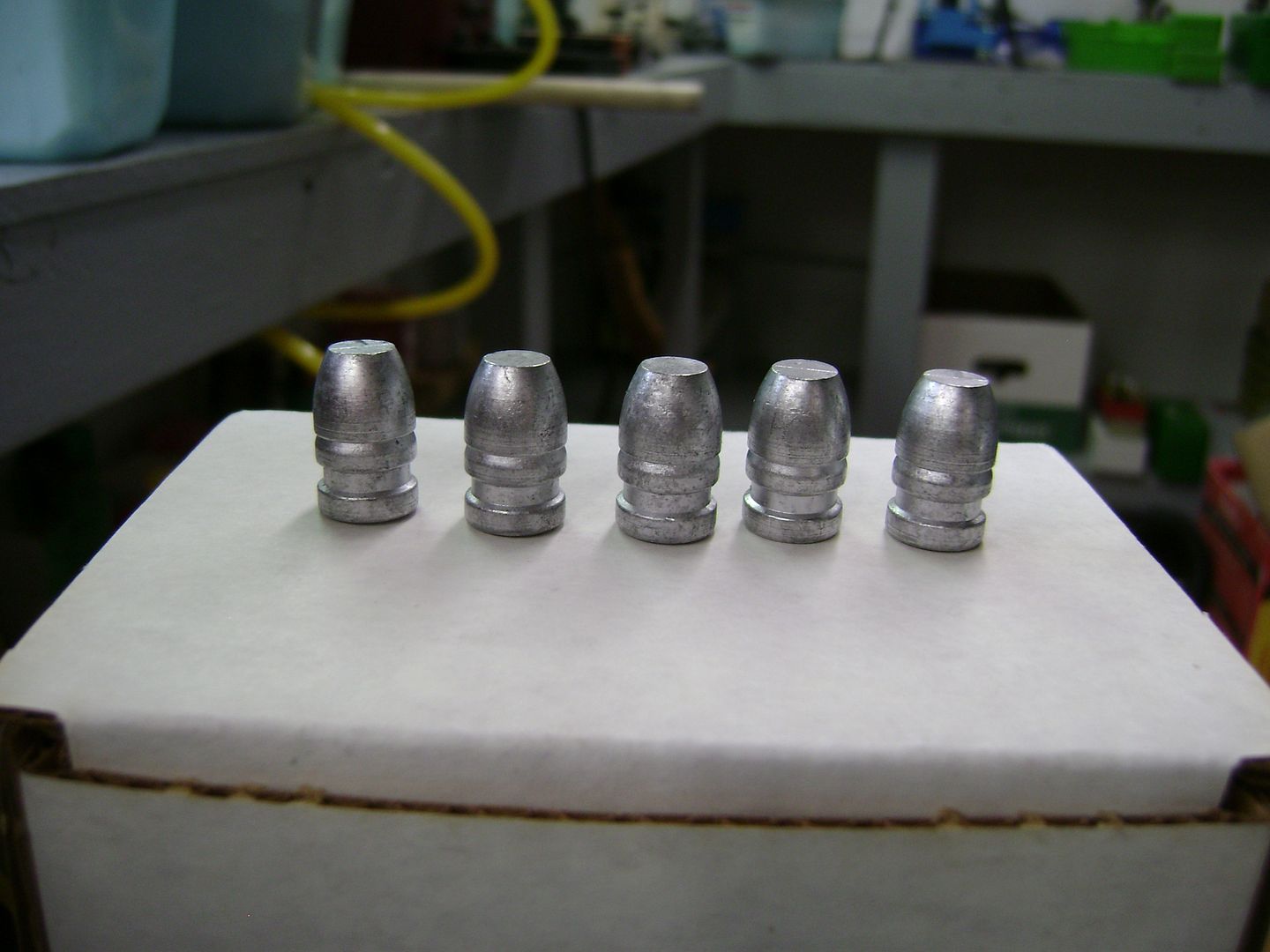

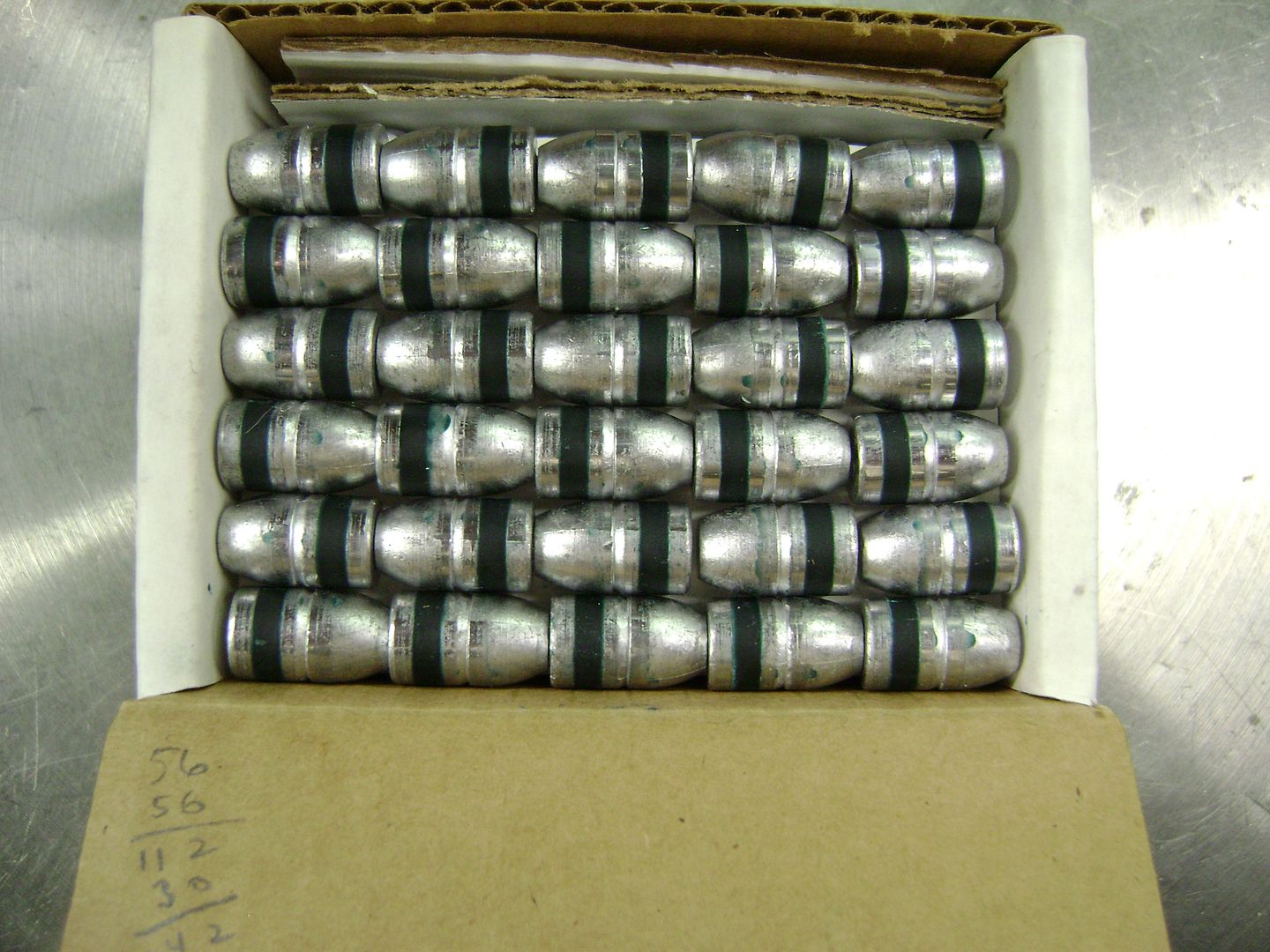

Sprue & dump box

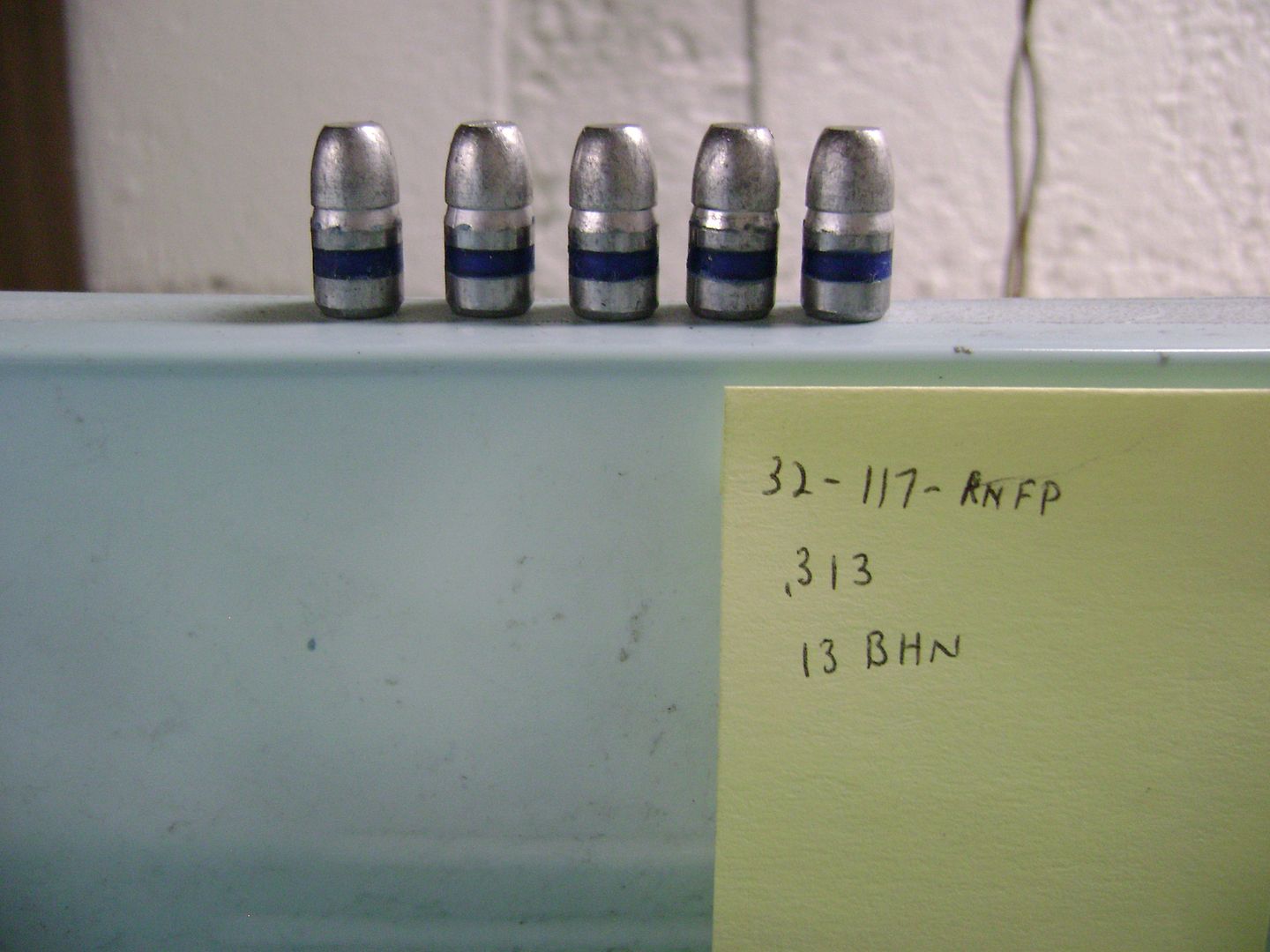

Results

Soooooooo came home Tuesday, turned the pot on, filled it with sprues & set the moulds on top. Next, let the dogs out, fix the fire & pour a large glass of water.

Once the lead was up to temp it’s only a few rounds with the moulds & they were also hot. For this session we did the three mould rotation, two 429421 moulds & on 358156, all 4 cavity. Two short sessions, one Tuesday evening & one this evening did the trick with 1300ea. 44s & 700ea. 38s.

The moulds

The pot

Sprue & dump box

Results