straight-shooter

New member

I've been running the Lee C309-200-1R Cast bullet in my M1 Garand in lead form only with no problems through a couple hundred rounds. I cast some more but this time I powder coated them. Keep in mind this bullet is a bore rider style bullet. Today after firing 28 rounds the 29th got stuck in the chamber and the rifle didn't go fully into battery.

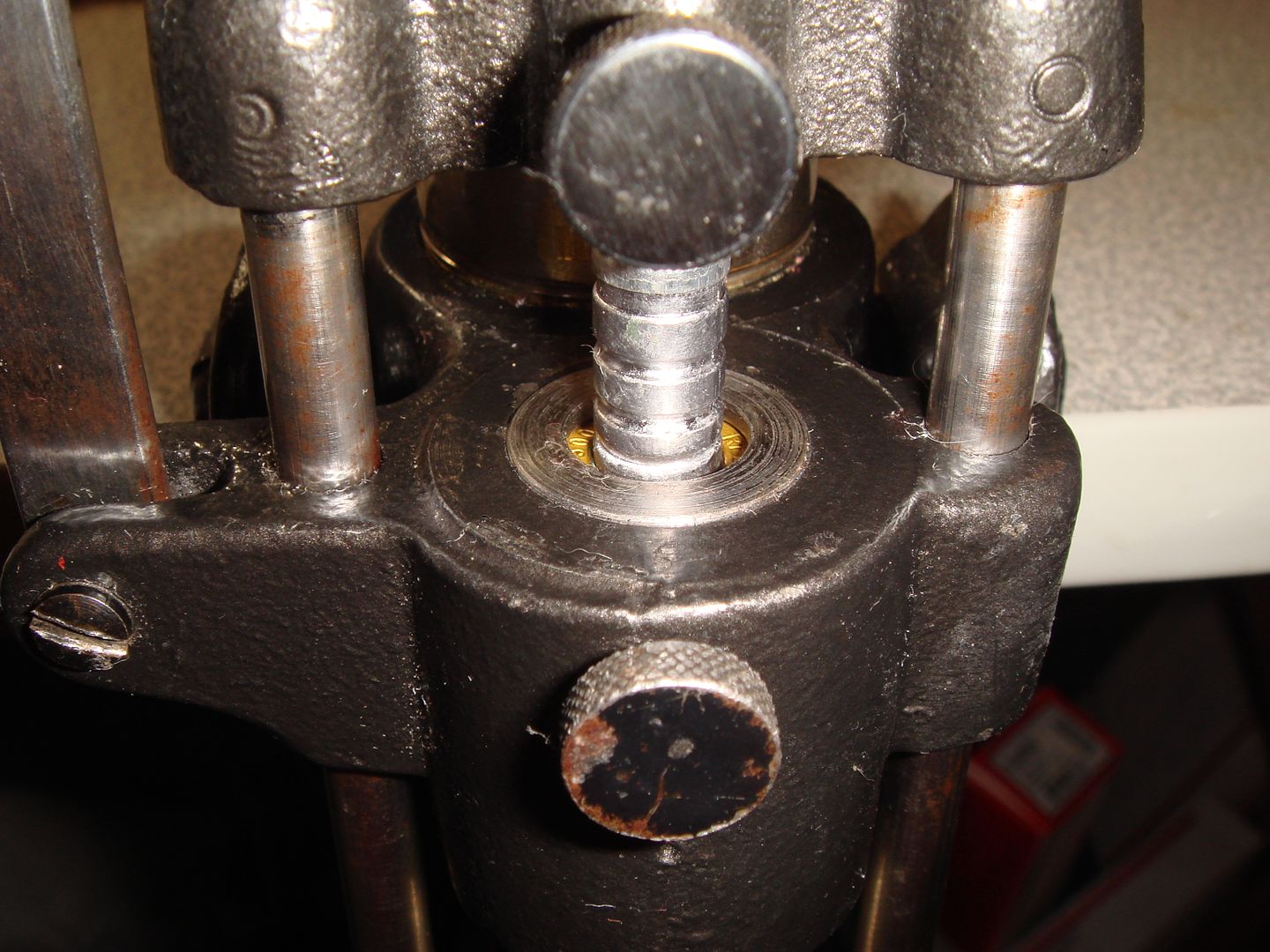

I pulled back on the bolt and extracted the round. Unfortunately the brass extracted but left the bullet in the chamber. I brought the rifle home and poked it out with a brass cleaning rod.

What this is telling me is it's probably not the best idea to powder coat a bore rider style bullet. Makes sense anyway.

I'm looking for others opinions on this hypothesis and also I would like a recommendation of a non bore rider style bullet that is also in the 200gr ballpark that may allow powder coat usage in the M1 Garand.

What cha say firingline ?

I pulled back on the bolt and extracted the round. Unfortunately the brass extracted but left the bullet in the chamber. I brought the rifle home and poked it out with a brass cleaning rod.

What this is telling me is it's probably not the best idea to powder coat a bore rider style bullet. Makes sense anyway.

I'm looking for others opinions on this hypothesis and also I would like a recommendation of a non bore rider style bullet that is also in the 200gr ballpark that may allow powder coat usage in the M1 Garand.

What cha say firingline ?