You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can Stainless Handguns rust?

- Thread starter sixgunnin

- Start date

Stainless steel is corrosion resistant not corrosion proof. My S&W revolvers do not have stainless steel trigger components. Stainless steel galls, does not through harden, is relatively soft compared to a tool steel. Some manufacturers do use stainless steel parts in the firing mechanism and I had problems with my Ruger MkII Stainless steel.

Last year I had taken the thing out to a full course 2700 match when in the slow fire stage of the NMC course, I was getting failures to fire!. The rim had a dent but round did not ignite. Luckily I had my Leatherman multi tool on my belt and I was able to remove the bolt. As I suspected, the firing pin was not going fully forward. Also, luckily, it is easy to take the firing pin out of a Ruger bolt. I took the firing pin out and I don't remember how I decided the problem was a mushroomed firing pin tang, but that was it. My multi tool has a file and I used that to file the back end parallel on both sides, install the firing pin, and got back in the game. Still I saved five rounds because I ran out of time.

I have only fired about 300-500 more rounds through the pistol when again I started having signs of a weak firing pin strike. This occurred in the rapid fire stages of the Bullseye match and I was able to complete all firing for the day.

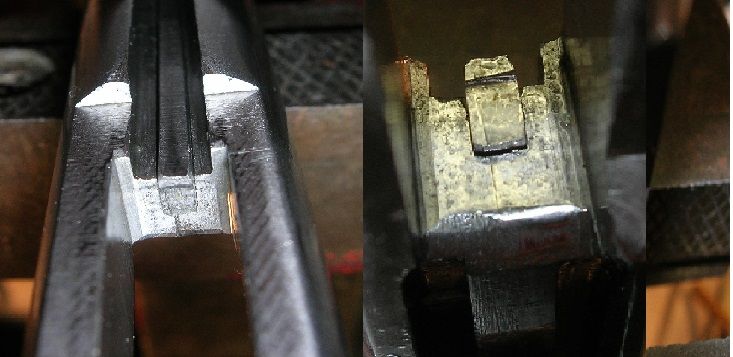

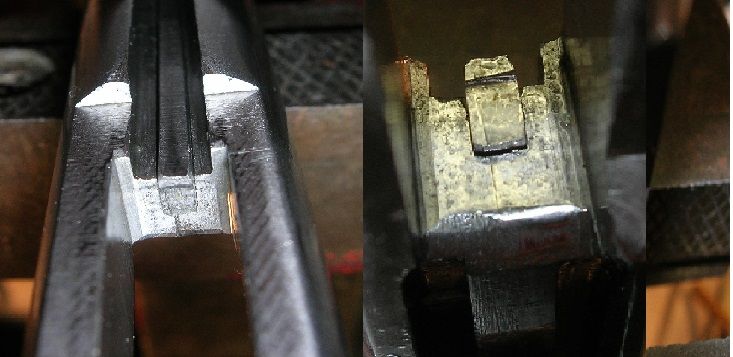

When I got back I took the bolt out and noticed that now, instead of the end of the firing pin being mushroomed, it had deformed due to the hammer strikes. As you can see in the pictures below, this firing pin has deformed to the point that there is insufficient firing pin protrusion to reliably ignite cartridges.

The factory mainspring has never been changed out nor the factory hammer. The internals are all original factory. I have concluded that whatever steels Ruger used in my stainless MKII, they are soft.

Anyway I got on the web and ordered a Volquartsen firing pin, according to the description it is made of A2 steel, which is a tool steel that is easily through hardened. Most commercial stainless steels tend to be surface harden able with a shallow hardness depth. (not the knife stainless steels), but I really don't need rust resistance in this application, I need a combination of hardness and toughness. I installed the Volquartsen firing pin and the pistol went back to shooting them in the middle.

Last year I had taken the thing out to a full course 2700 match when in the slow fire stage of the NMC course, I was getting failures to fire!. The rim had a dent but round did not ignite. Luckily I had my Leatherman multi tool on my belt and I was able to remove the bolt. As I suspected, the firing pin was not going fully forward. Also, luckily, it is easy to take the firing pin out of a Ruger bolt. I took the firing pin out and I don't remember how I decided the problem was a mushroomed firing pin tang, but that was it. My multi tool has a file and I used that to file the back end parallel on both sides, install the firing pin, and got back in the game. Still I saved five rounds because I ran out of time.

I have only fired about 300-500 more rounds through the pistol when again I started having signs of a weak firing pin strike. This occurred in the rapid fire stages of the Bullseye match and I was able to complete all firing for the day.

When I got back I took the bolt out and noticed that now, instead of the end of the firing pin being mushroomed, it had deformed due to the hammer strikes. As you can see in the pictures below, this firing pin has deformed to the point that there is insufficient firing pin protrusion to reliably ignite cartridges.

The factory mainspring has never been changed out nor the factory hammer. The internals are all original factory. I have concluded that whatever steels Ruger used in my stainless MKII, they are soft.

Anyway I got on the web and ordered a Volquartsen firing pin, according to the description it is made of A2 steel, which is a tool steel that is easily through hardened. Most commercial stainless steels tend to be surface harden able with a shallow hardness depth. (not the knife stainless steels), but I really don't need rust resistance in this application, I need a combination of hardness and toughness. I installed the Volquartsen firing pin and the pistol went back to shooting them in the middle.

g.willikers

New member

There's all kinds of things called stainless.

Some better resistant to rust than others.

Judging from my scuba equipment, the only truly rust proof stuff is made of brass and chrome (nickle?)

It would probably be a bad idea to leave your stainless gun out in the rain for long or not clean and dry it afterward.

Some better resistant to rust than others.

Judging from my scuba equipment, the only truly rust proof stuff is made of brass and chrome (nickle?)

It would probably be a bad idea to leave your stainless gun out in the rain for long or not clean and dry it afterward.

I recall reading that there are something like 150 grades of stainless steel for general use plus specialty alloys, there is precipitation hardening -I remember reading that my AMT Hardballer was made out of 17-4, that being particularly suitable for firearms. Also I have read that some stainless guns use plated internal parts.

Slamfire , your third sentence is incorrect. There are SS tool steels ,there are through hardening SS .Yes they can rust , Galling [ cold welding ] was common in the early days of SS guns but they pick the better SS types for that now.

The choice of a SS part has many variables ,cost , ease of manufacture, etc.

I'm a metallurgist If you have questions about that subject ask me I'll be happy to respond .

If you have questions about that subject ask me I'll be happy to respond .

The choice of a SS part has many variables ,cost , ease of manufacture, etc.

I'm a metallurgist

Pathfinder45

New member

I have a stainless Vaquero 45 that I have experimented with to see how much neglect it could take and still be reliable. It lives in a leather holster at all times when it's not being shot. It has been put away uncleaned and rained on. The worst thing I have ever done to it is to fire a full box of genuine black-powder cartridges and then put it away in the holster for somewhat over a month, with loaded BP ammo still in the cylinder. On purpose. When I finally took it out, it didn't look good at all. The cylinder would turn sluggishly, but certainly not spin. I said to myself, "Now you've done it. You're going to regret this." But it cleaned up just fine without any rust. Everything was dirty as heck and the loaded rounds were somewhat corroded, by not ruined. Now the experiment is over. I don't feel compelled to try saltwater. I just wanted to know if the Stainless Vaquero would be reliable in the worst extended conditions that I could imagine myself in. The stainless Vaquero passed the test.

Slamfire , your third sentence is incorrect. There are SS tool steels ,there are through hardening SS .Yes they can rust , Galling [ cold welding ] was common in the early days of SS guns but they pick the better SS types for that now.

The choice of a SS part has many variables ,cost , ease of manufacture, etc.

I'm a metallurgist If you have questions about that subject ask me I'll be happy to respond .

Very interesting, seems technology has moved on, but I have stayed rooted in place. I am curious to know which SS through harden acceptably, and of SS combinations don't gall.

A scratch test on my Ruger MKII stainless shows that it is made of softer materials than my blued MKII.

Slamfire,

My dad has a MkII that requires cleaning every 200-300 rounds How is yours that way?

I must have OCD because I always clean up my firearms before putting them away. I do not know when I have ever fired more than 300 rounds of 22lr through any of my MKII's before cleaning. I met a young man who claimed to have shot one day bang a thons. In one day he shot a 5000 round case of 22LR's through his MKIII. This was when 22LR was cheap. He did a simple calculation and claimed his MKIII had at least 100,000 rounds through it. I seem to remember something trivial was replaced on his MKIII, but I can't remember what. I did examine his MKIII and it was filthy compared to mine, lots of powder residue and caking.

I have had malfunctions in cold weather. The lower cost 22LR rounds are externally coated with a wax. Not only the bullet but the case. Expensive match 22LR is greasy from bullet to rim. Eley has different lubricants depending on the application. They claim to have a special lube for biathon shooters (very cold weather) and this claim for semi auto 22lr's:

2015 Product Guide

http://www.eley.co.uk/eley-match

With its innovative hollow nosed profile, the ELEY subsonic hollow projectile delivers unequalled expansion characteristics, resulting in short penetration with outstanding stopping power; essential features for vermin control .The non-greasy lubricant provides smooth operation in semi-automatic rifles and improves functioning in all weather conditions.

This lubricant vaporizes to a gas when the cartridge is fired, particularly the lubricant on the bullet. When the breech opens up under pressure, some gas is vented into the action and the lubricant condenses. This is particularly bad in cold weather as both waxes and greases become hard in cold weather. This will cause failures to feed as the bolt is slowed down by gooey or hard lube. To shoot Bullseye matches in 40 ish weather, I have tested the stuff and found some brands that take longer to cause malfunctions. If this is the problem, I recommend spraying oil on the bolt and receiver interior, and wiping it off, to dissolve as much of the condensed greases and waxes as possible. I typically run my 22lr's very dry in cold weather.

As others have stated, some stainless alloys are more corrosion resistant than others. The alloys used in guns are typically optimized much more for production costs rather than corrosion resistance. They are still much more corrosion resistant than carbon steel.

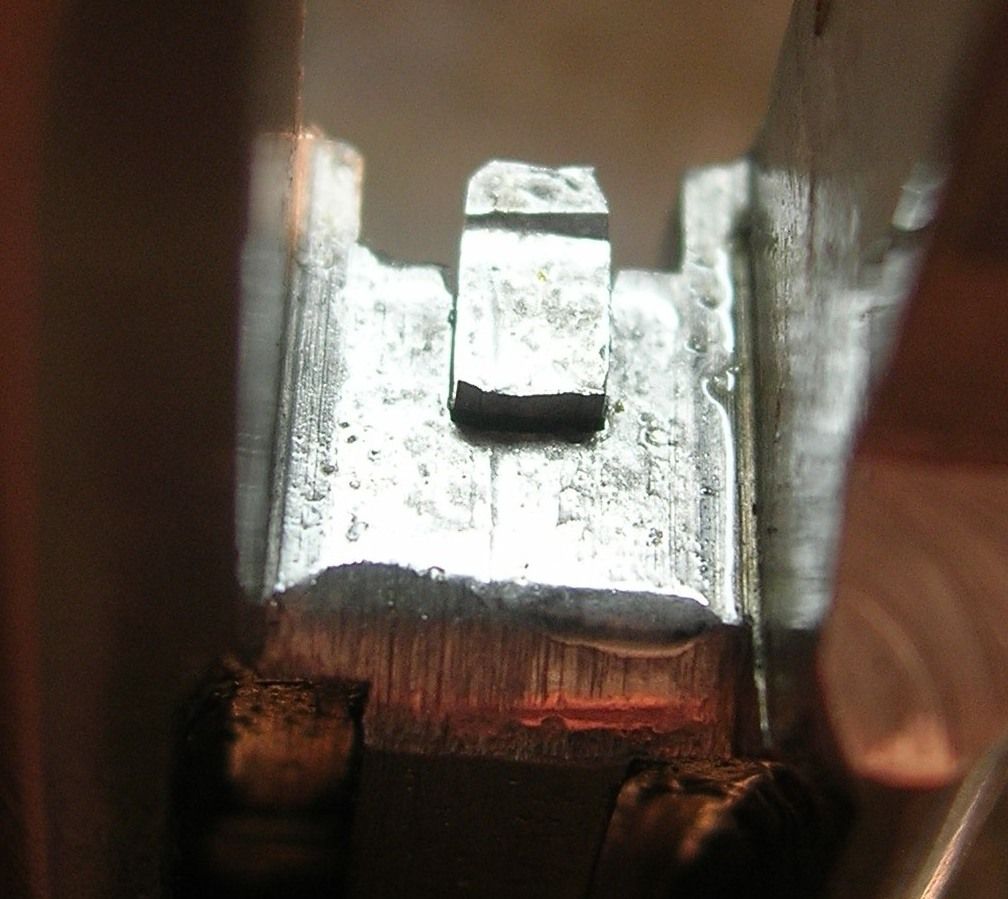

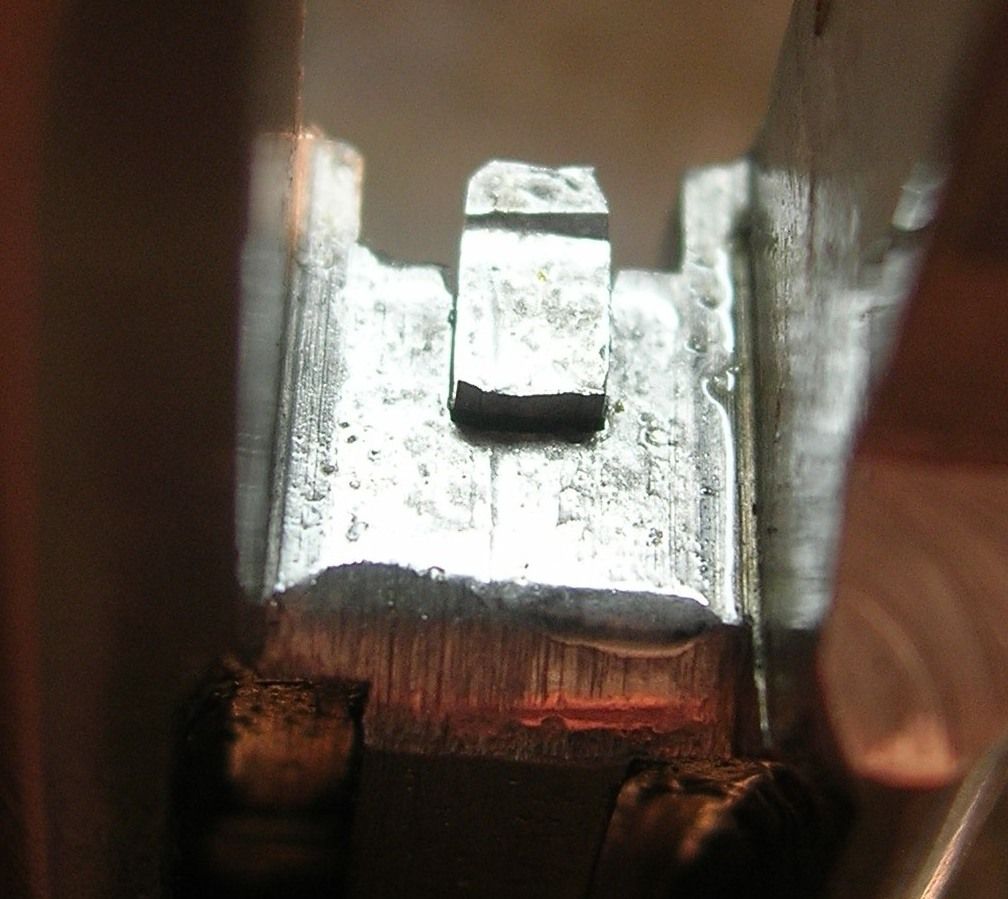

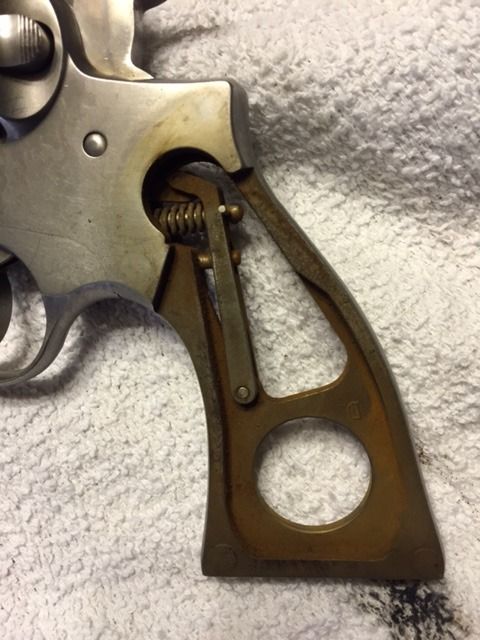

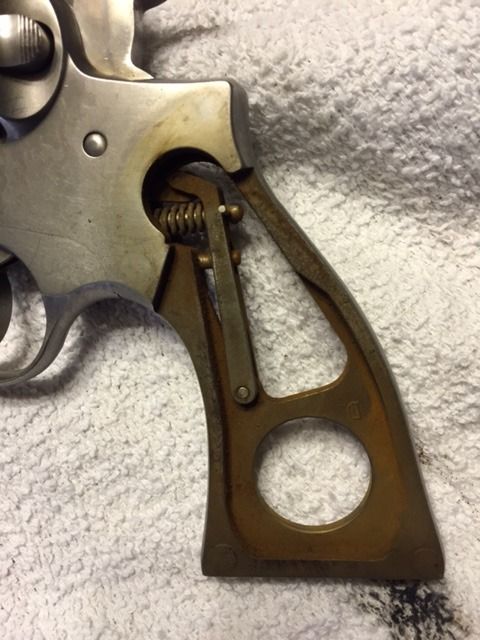

Couple of pictures of a stainless Ruger Redhawk that looked great on the outside but had obviously had some water under the grips at some point in it's life. Someone took great care in keeping the outside wiped off, just never looked at the internals. Trigger actually wasn't real bad, just a little "scratchy" feeling. Feel free to draw your own conclusions on whether stainless will rust.

Note: It cleaned up nicely, some slight pitting that isn't visible externally, but didn't affect anything.

Anyone from New Orleans that saw guns that went under in Hurricane Katrina will testify as to how quickly stainless guns will rust.

Couple of pictures of a stainless Ruger Redhawk that looked great on the outside but had obviously had some water under the grips at some point in it's life. Someone took great care in keeping the outside wiped off, just never looked at the internals. Trigger actually wasn't real bad, just a little "scratchy" feeling. Feel free to draw your own conclusions on whether stainless will rust.

Note: It cleaned up nicely, some slight pitting that isn't visible externally, but didn't affect anything.

Anyone from New Orleans that saw guns that went under in Hurricane Katrina will testify as to how quickly stainless guns will rust.

Last edited:

JoeSixpack

New member

Stainless guns will rust, but in my experience are pretty resistant.

I'd say under normal circumstances you'd probably have to neglect a stainless gun to have problems.

sometimes you get red rust other times black, the black rust is actually somewhat beneficial as it's hard not flaky and keeps from rusting more.

But man does it look horrid.

I always prefer stainless when I can get it because I like the look, it's rust resistant, and is almost always offered bare so no paint to wear off (although you can paint it till if you want)

A lot of "stainless" guns are really only guaranteed to have the major components stainless.. barrel, slide, frame, etc

smaller parts aren't always stainless, I don't know if they make "stainless" springs, but they do make chromed ones.

I'd say under normal circumstances you'd probably have to neglect a stainless gun to have problems.

sometimes you get red rust other times black, the black rust is actually somewhat beneficial as it's hard not flaky and keeps from rusting more.

But man does it look horrid.

I always prefer stainless when I can get it because I like the look, it's rust resistant, and is almost always offered bare so no paint to wear off (although you can paint it till if you want)

A lot of "stainless" guns are really only guaranteed to have the major components stainless.. barrel, slide, frame, etc

smaller parts aren't always stainless, I don't know if they make "stainless" springs, but they do make chromed ones.

I'd always thought that SS did not rust. It is fairly resistant to most environments, but salt air and humidity will begin to pit the finish. It is, however, both easy to repair and prevent.

If carrying in the above environment it is advisable to wipe down with an oily cloth after a day's wear (concealed or otherwise). You will avoid any problem.

If carrying in the above environment it is advisable to wipe down with an oily cloth after a day's wear (concealed or otherwise). You will avoid any problem.

Bill DeShivs

New member

Some stainless steels will not rust.

Most stainless that is used in guns can rust under the right conditions

They don't make chromed springs. Or, if they do-they shouldn't. Chromium is not flexible enough for springs and plating promotes hydrogen embrittlement.

400 series stainless is through hardening, as is 154 CM and other steels used in knife blades.

Most stainless that is used in guns can rust under the right conditions

They don't make chromed springs. Or, if they do-they shouldn't. Chromium is not flexible enough for springs and plating promotes hydrogen embrittlement.

400 series stainless is through hardening, as is 154 CM and other steels used in knife blades.

There's usually a trade-off between corrosion resistance and strength; alloys that are more resistant to corrosion are often weaker, while stronger alloys are more prone to rust. Thanks to modern metallurgy, there are alloys that are both very strong and highly corrosion resistant, but they tend to be prohibitively expensive and hard to work. (I'd still love to see a machinist make an Inconel or Hastelloy 1911 just because, but it'd be ridiculously expensive for no quantifiable benefit...)

One thing that you have to consider too is that stainless loses its resistance if it's contaminated with oxidation (such as by touching oxidized carbon steel). When we weld stainless, we can only clean our joints with stainless wire brushes that have never touched non-stainless steels; otherwise oxidation can be transferred from the bristles to the joint, and the welds will rust.

Are you 100 percent sure that every piece of metal in your gun is stainless? (I can pretty much promise you they're not...)

One thing that you have to consider too is that stainless loses its resistance if it's contaminated with oxidation (such as by touching oxidized carbon steel). When we weld stainless, we can only clean our joints with stainless wire brushes that have never touched non-stainless steels; otherwise oxidation can be transferred from the bristles to the joint, and the welds will rust.

Are you 100 percent sure that every piece of metal in your gun is stainless? (I can pretty much promise you they're not...)

There are three general categories of stainless steels...Austenitic, Ferritic and Martensitic, with many stainless steels within those three categories. Martensitic stainless steels like 440C (commonly used in pocket knife blades) will harden all the way through. "Stainless Steel" is not just one alloy, it is many.Stainless steel galls, does not through harden, is relatively soft compared to a tool steel.

Pathfinder45

New member

Preferentially, I like the looks of blued steel firearms much better than stainless. With reasonable care, there is no worry of corrosion. One of the reasons I treated my stainless Vaquero so badly, was to see for myself if stainless had any advantage. Its neglectability is much better than blued steel. Still, I only bought it because it was an excellent deal that I couldn't pass up. It was exactly the gun I wanted, except it was stainless. If I were to buy another, I would hold out for blued steel, and take better care of it. It may not be perfectly rust-proof. But it sure seems to be in this case. It's reliability in extended adverse conditions has been undeniable.

Galling is not limited to SS. Galling will be worse if both of the moving parts are soft .Special lubes were used for early SS guns like RIG + P.

SS types are not the easiest to machine so often a free machining grade [higher sulfur grade] 303 0r 416 is used .

Corrosion is very dependent on surface oxides such as chrome oxide on SS. disrupt the oxide and rust can start. Proper manufacture of SS is to only use equipment , cutting tools etc only for the SS. Final step is to 'passivate' by treating with acid to remove things like iron particles . If you put iron on SS ,when the iron rusts that rust will continue , eating down through the chrome oxide and down into the SS.

SS types are not the easiest to machine so often a free machining grade [higher sulfur grade] 303 0r 416 is used .

Corrosion is very dependent on surface oxides such as chrome oxide on SS. disrupt the oxide and rust can start. Proper manufacture of SS is to only use equipment , cutting tools etc only for the SS. Final step is to 'passivate' by treating with acid to remove things like iron particles . If you put iron on SS ,when the iron rusts that rust will continue , eating down through the chrome oxide and down into the SS.