I just got a gun and it is an old mauser that was drilled for scope mounts. Well when the "smith" drilled it he drilled all the way into the chamber. The gun shoots great and shells eject with no difficulty at all. But my question is that if there is a way to repair the place that he drilled too deep? Each piece of brass has a spot showing where it expands into the hole slightly. Again shoots great and brass ejects easilly. It is just that i know it is there

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can it be fixed?

- Thread starter hbhobby

- Start date

Goatwhiskers

New member

The only way to repair that is to replace the barrel. That gun is quite unsafe in its present condition. GW

Chamber porting. We joked about it in gunsmithing school.

Seriously, it's time to rebarrel it. If the case fails, pressure could vent through that screw head and knock off the scope base, scope ring and scope. No need for you or others to be injured. Until you get that done, don't shoot it anymore.

Seriously, it's time to rebarrel it. If the case fails, pressure could vent through that screw head and knock off the scope base, scope ring and scope. No need for you or others to be injured. Until you get that done, don't shoot it anymore.

g.willikers

New member

I once had the same problem with a .22 rimfire.

I used a good quality screw that filled the over drilled hole completely and well, without, of course, intruding on the chamber.

And made sure the bottom of the errant hole and screw were very smooth and clean, without any kind of irregularity.

I check it constantly for beginning cracks and other suspicious conditions, but have yet to see one.

But it's not a gun that gets used much.

It's also a much less powerful of a caliber than the Mauser.

So, for your case, it might require a better solution.

If you go this route, beware of the risks.

Your results might not be as good as mine.

Lawyer speak.

I used a good quality screw that filled the over drilled hole completely and well, without, of course, intruding on the chamber.

And made sure the bottom of the errant hole and screw were very smooth and clean, without any kind of irregularity.

I check it constantly for beginning cracks and other suspicious conditions, but have yet to see one.

But it's not a gun that gets used much.

It's also a much less powerful of a caliber than the Mauser.

So, for your case, it might require a better solution.

If you go this route, beware of the risks.

Your results might not be as good as mine.

Lawyer speak.

Last edited:

Jim Watson

New member

There used to be a good deal of discussion on repair of scope mount holes drilled through into chambers. But we are more cautious now.

I won't go into detail because if I told you how and it didn't hold, your lawyer would track down my computer and sue me.

I won't go into detail because if I told you how and it didn't hold, your lawyer would track down my computer and sue me.

A shooting bud of mine decided to build up a faux Marine Sniper rifle.

He has a very hard to find Unertl scope

Found a USMC Sedgley barrel

OOPS! the gunsmith drilled the rear base holes a little to deep in the chamber!

The sequence of rounds that it took to blow through the little bit of metal left under the screw hole.

He has a very hard to find Unertl scope

Found a USMC Sedgley barrel

OOPS! the gunsmith drilled the rear base holes a little to deep in the chamber!

The sequence of rounds that it took to blow through the little bit of metal left under the screw hole.

I just got a gun and it is an old mauser that was drilled for scope mounts

I will assume the rifle does not have a scope base mounted, I do believe there would be a hole punched through the case if the screws were not in place.

I do not know what an Old Mauser is. I will not drill and tap a receiver with the barrel installed. It has everything to do with a blind end hole. There is something about the expression on someone's face that says "I just snapped a tap" that causes me to want to avoid the experience.

Off the Internet, in a shop the question was "Who wants these barrels and if you had them what would do with them?" I knew if I had a use for the barrels the price would have gone up from free if you haul them off to a price that would cause me to loose interest.

I suggested the chambers be cut off and recut/reamed to make chamber gages. Then I qualified my next answer with "I would not do 'it', but etc..", not one of the three was the condensing type, the barrels are still there for the hauling off.

F. Guffey

Most gunsmiths drill and tap with the barrel installed; unlike some folks, we are smart enough to set up a drill press so the hole doesn't go through into the chamber.

As for a fix, it can be done, though I don't necessarily recommend it. Make a long screw (6x48, I assume) from fairly soft steel and run it into the hole until the end just protrudes into the chamber. Then, very carefully, use a chambering reamer to cut off the end down to the chamber wall. I have never done it (see above) but have seen one that was done that way and it worked fine. Alternatively, the screw could be cut off flat at the bottom end, screwed down until the end was flat with the chamber, cut off at the top and staked to keep it from moving.

Jim

As for a fix, it can be done, though I don't necessarily recommend it. Make a long screw (6x48, I assume) from fairly soft steel and run it into the hole until the end just protrudes into the chamber. Then, very carefully, use a chambering reamer to cut off the end down to the chamber wall. I have never done it (see above) but have seen one that was done that way and it worked fine. Alternatively, the screw could be cut off flat at the bottom end, screwed down until the end was flat with the chamber, cut off at the top and staked to keep it from moving.

Jim

cut off at the top and staked to keep it from moving.

I would question the smartness of that method and or technique after staking? drill another hole? that would be 4 holes. add the diameter of 4 holes and add together, I would guess the receiver would just about be cut in half across the top. I have seen that.

F. Guffey

I will add to my previous post that IF I ever did fix that hole as I said (not recommended) I would not try to use that screw hole again. If I had to drill another hole, I would move it at least 1/4 inch away and use a different base. If that wasn't possible, I would simply tell the customer that I would not mount a scope on that rifle, period.

Jim

Jim

kilimanjaro

New member

Yes, you can 'fix' it. Just re-barrel and have a competent smith do the scope mounting. Cost will be just a couple hundred bucks, probably.

Or, you can 'jury rig' it with plugs and screws, thereby delaying the day you wreck your expensive scope mounts, telescope, and injure yourself or a bystander with a blown screw flying around.

Or, you can 'jury rig' it with plugs and screws, thereby delaying the day you wreck your expensive scope mounts, telescope, and injure yourself or a bystander with a blown screw flying around.

The problem I see with drilling a larger hole and using a plug screw is that the brass can still be extruded into the original screw hole under pressure and create extraction problems. That would probably not be the case with a .079" gas port, but I think it might be with a scope screw hole twice that size.

Jim

Jim

Gunplummer

New member

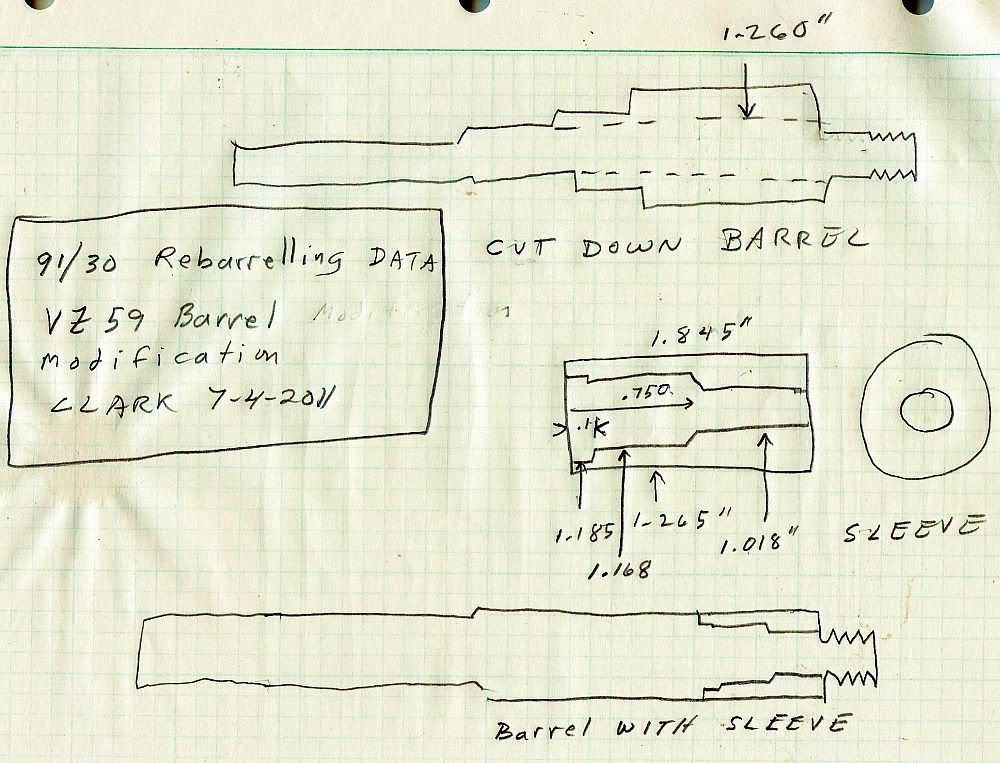

I have added chamber areas to barrels many times to use good barrels. Nothing is written in stone. It is a matter of measuring and THINKING about what you are doing. I picked up a Type 99 Arisaka at a yard sale once that had the barrel set back and was converted to .300 Savage. The neck of the fired brass had a slight ring around it, kind of like a slight, narrow "O" ring recess would make. I knew the guy blended the two neck dimensions together and the original was slightly larger. It extracted fine, shot very well @ 100 yards. If I posted a picture of that brass on this forum, people would be freaking out about new barrels, headspace, and who knows what. If given the chance to inspect that gun, I probably would repair it. I always like posts from Clark. He does not seem to be a "Bolt on" gunsmith.

Hindsight is 20-20!Most drilling machines(I prefer a Bridgeport) have an amazing device called a quill stop!But,OP,you did not drill the holes,now you have a problem.

Myself,when it comes to chamber,lockup,trigger,safety,etc...the parts of a gun that can hurt folks,it just needs to be right.No half bassing.Its not just you,some kid may end up shooting that rifle.

The decision you have to make,is do you put more money into it,or cut your losses,That is up to you.If it is a military stepped barrel,there are a lot of them laying under benches and in corners.You can find one,have it screwed in,and headspace checked.I would not expect to pay a lot for the barrel,between a 12 pak and $50.Your smith will charge what he charges.

There are number of choices for pre-threaded,short or long chambered Mauser replacement barrels.I like Lothar Walther,about $270 or so,go to the site.Cheaper ones are available.

Bummer.

Myself,when it comes to chamber,lockup,trigger,safety,etc...the parts of a gun that can hurt folks,it just needs to be right.No half bassing.Its not just you,some kid may end up shooting that rifle.

The decision you have to make,is do you put more money into it,or cut your losses,That is up to you.If it is a military stepped barrel,there are a lot of them laying under benches and in corners.You can find one,have it screwed in,and headspace checked.I would not expect to pay a lot for the barrel,between a 12 pak and $50.Your smith will charge what he charges.

There are number of choices for pre-threaded,short or long chambered Mauser replacement barrels.I like Lothar Walther,about $270 or so,go to the site.Cheaper ones are available.

Bummer.

Gunplummer

New member

I would not give him the 12 pack, you may get another hole through the chamber.

James K. adding a plug to his plugged screw would have plugged the hole. He could have started with a plug that was too long and worked from there.The problem I see with drilling a larger hole and using a plug screw

F. Guffey

Jim Watson

New member

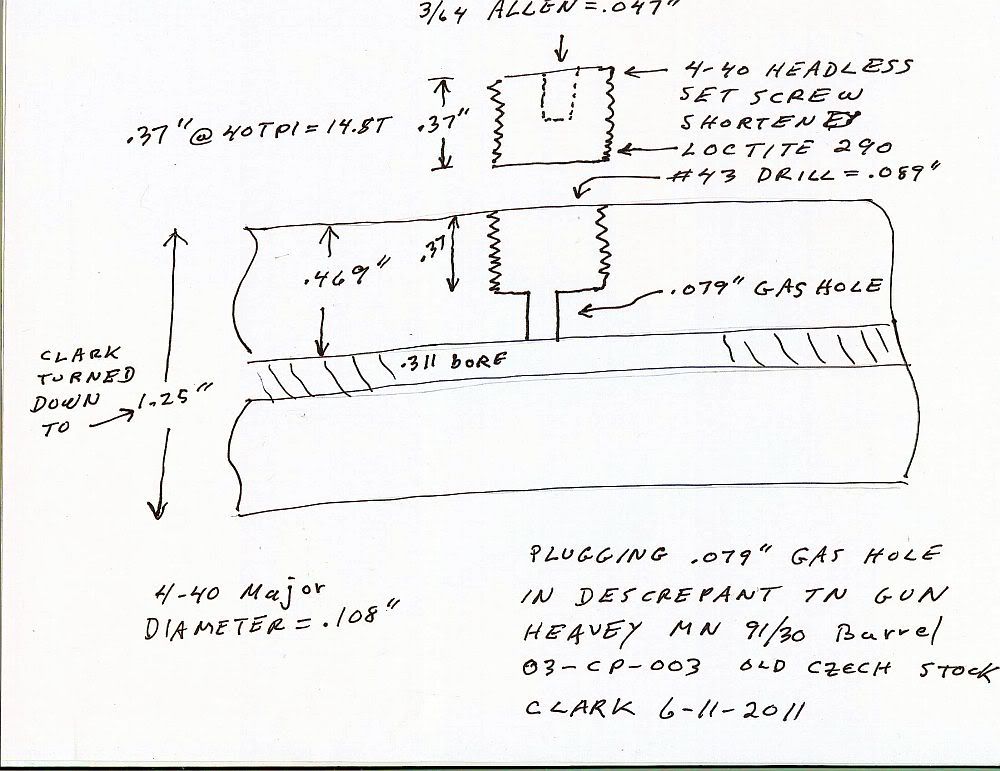

Now that it is out in the open, the version I saw - Gunsmith Kinks or a gunboard - had a smooth ended set screw flush with the chamber wall, with another set screw in behind it to jam it hard into the threads. High strength Loctite, of course. Seems like Loctite has largely replaced jam nuts and screws, but they do have a place.

There is a guy on THR with a hole in his barrel, but it sounds like it is into the rifling. I guess if you can plug a gas port you can plug a foulup port.

There is a guy on THR with a hole in his barrel, but it sounds like it is into the rifling. I guess if you can plug a gas port you can plug a foulup port.