To start with, I don't know much about bolt action guns. I've owned about 20 firearms over the past 20 years, but just got my first turn-bolt about a month ago.

I got a Savage .223 that came with a cheap non-Accu-stock. I replaced it with a Boyd's walnut stock. I like the stock, but the gun shifts a bit in it. Looking along the barrel channel, sometimes the barrel is free-floated right down the middle. Other times, it appears to touch or almost touch the right side.

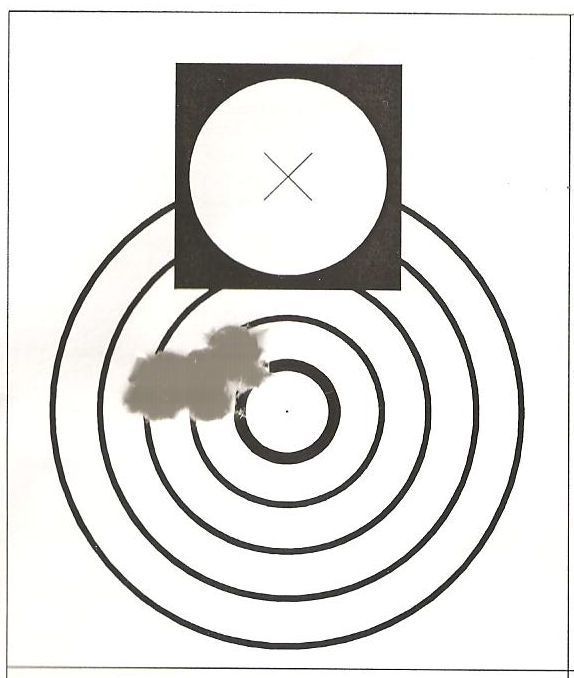

I want to address this, but have no experience with this kind of thing. The gun is mostly for longer range plinking (no serious target work or varminting), and I don't necessarily need the absolute best option if it's difficult or expensive.

What are some options I could look into?

I got a Savage .223 that came with a cheap non-Accu-stock. I replaced it with a Boyd's walnut stock. I like the stock, but the gun shifts a bit in it. Looking along the barrel channel, sometimes the barrel is free-floated right down the middle. Other times, it appears to touch or almost touch the right side.

I want to address this, but have no experience with this kind of thing. The gun is mostly for longer range plinking (no serious target work or varminting), and I don't necessarily need the absolute best option if it's difficult or expensive.

What are some options I could look into?

Last edited: