loademwell

New member

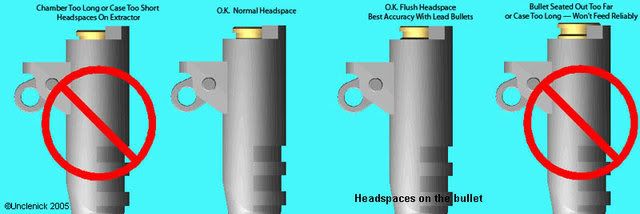

I just put together a few reloads using 124 (purchased) lead projectiles that are all ready lubed. I loaded them using the data for 125 grain lead rounds. The book said that the oal. should be 1.115 Myne were at 1.110

I put together about 5 and headed out to the range. (It was cold) lol, anyway, I never got a chance to shoot them. I loaded up the clip and put it into my Taurus PT92. When I tried to unload (take out a live round) it got all jamed up. I am unable to pull back the slide and kick that round out.

I had this happen in my dear rifle $200 to get it all fixed.

Im tempted to attempt to shoot it and see if it will go boom. (I was on the lower charge side) Any idea on why this happened or if this should be safe to shoot?

I put together about 5 and headed out to the range. (It was cold) lol, anyway, I never got a chance to shoot them. I loaded up the clip and put it into my Taurus PT92. When I tried to unload (take out a live round) it got all jamed up. I am unable to pull back the slide and kick that round out.

I had this happen in my dear rifle $200 to get it all fixed.

Im tempted to attempt to shoot it and see if it will go boom. (I was on the lower charge side) Any idea on why this happened or if this should be safe to shoot?

Last edited: