Rangefinder

New member

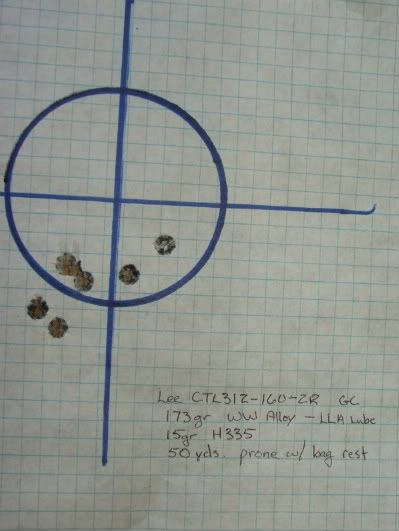

All righty then. I've finally had a few minutes to start working up a load for my 7.62x39 hand casts. First Test shown.

Try as I might, there is limited info to be found with regard to load data on the 7.62x39 using cast bullets. I have several, but out of the half-dozen sets, only one had powder I currently use---a case stuffed full of IMR4895. Well, I'm not big on using more powder than necessary, so I had to develop something not on the books. My .32 Win SP uses hand casts of nearly identical weight with a light load since that one isn't a GC bullet. The case volume is larger, but by comparing load data between that case and the ratio of volume increase/pressure, etc, I settled on a starting load with a powder I have plenty of and already use in multiple loads.

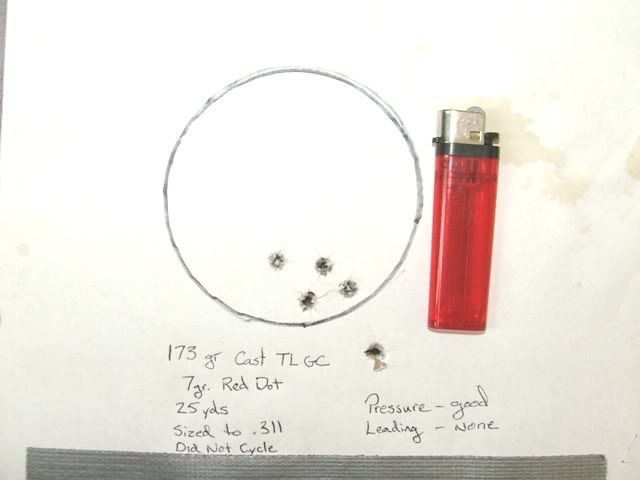

---7gr Red Dot.---

The low flyer is entirely my fault. It was the first shot and I am always a little flinchy firing a new load that doesn't have any supporting data. After confirming everything was still in one piece, the following 4 shots went right where they were suppose to.

Just in case you can't make out all my writing on the photo...

173gr TL GC bullet sized to .311

7gr. Red Dot

25 yds

Pressure Good

DID NOT CYCLE (rifle is a Norinco Mak-90 all milled)

No leading found

Additional not written down---Bullets are water dropped WW. BHN hitting around 16.

I didn't expect the pressure to be high enough to cycle the action--and that was intentional. Now that I've established the starting load and everything else checks out, I can increase pressures. I'll keep things posted as I work up to a fully-functional load. So far--so good.

Next I'll go up in grains by .5 till I get reliable cycling with everything else the same. Then I'll start working on POA/POI adjustments for distances. But that's all for the moment.

Last edited: