bamaranger

New member

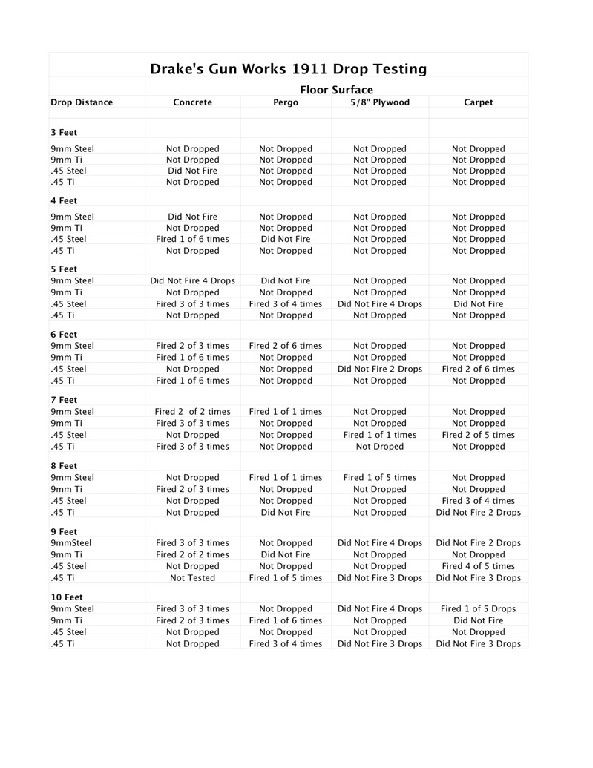

There is another thread running about what amounts to condition 1 v. condition 2 carry with semiauto pistols, and that got me thinking about the various 1911 "series" and their safety features. I about half hijacked that thread, so to avoid any further confusion I started this one.

There are at lease 3 1911 "series" that I can identify, tell me if there's more: 1)early GI and original pistols, 2)series 70, and series 80.

I am particulalry interested in how all that relates to Condition Two carry, the purpose of the half cock notch (hammer stop notch?), etc.

I had always believed that Condition Two was a no-no. A blow to the hammer at full rest could overcome the inertial firing pin by direct contact, or....if the notch was used, a similar blow could shear the notch and allow the hammer to fall and the pistol to fire as well.

What Have I got right or wrong with that and how did the series 70 and 80 pistols change the theory?

There are at lease 3 1911 "series" that I can identify, tell me if there's more: 1)early GI and original pistols, 2)series 70, and series 80.

I am particulalry interested in how all that relates to Condition Two carry, the purpose of the half cock notch (hammer stop notch?), etc.

I had always believed that Condition Two was a no-no. A blow to the hammer at full rest could overcome the inertial firing pin by direct contact, or....if the notch was used, a similar blow could shear the notch and allow the hammer to fall and the pistol to fire as well.

What Have I got right or wrong with that and how did the series 70 and 80 pistols change the theory?